Stock Market | FinancialContent Business Page

Optomec will be showcasing its latest printing solutions for 3D Printed Metal as well as Printed Electronics at RAPID +TCT 2023. Optomec’s LDH 3.1 Directed Energy Deposition print head will be on display for 3D Printed Metal. This allows users to adjust the spot size during a build, repair or maintenance. Optomec’s latest Aerosol Jet will be announced for customers of Printed Electronics.® Print head that is compact and low maintenance for production applications. Optomec’s new solutions will be shown in Booth 5027.

This press release includes multimedia. View the full release here: https://www.businesswire.com/news/home/20230502005991/en/

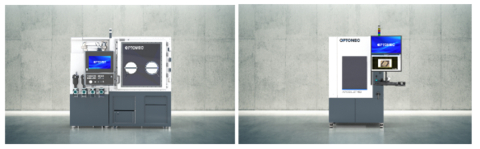

The CS250 (left) machine for Metal Additive Manufacturing and the Aerosol Jet HD2 (right) machine for Printed Electronics. Photo courtesy Optomec.

The LDH-3.1 printhead delivers superior 3D Metal builds by allowing you to change the laser spot size or power density remotely. This allows the operator optimize deposition in terms of print speed and metalurgical properties. The larger areas of the print can use a bigger laser spot to achieve a faster deposition rate, while the smaller laser spots can be used on the finer features. This can be accomplished remotely, without breaking the inert atmosphere of the machine’s build chamber.

The new Endurance Print Head for Aerosol Jet Machines delivers a compact and simplified printhead for electronics production. The new design has been optimized for longer running runs and faster maintenance. It comes with a ultrasonic atomizer to use on various inks. Optomec’s Printed Electronics machines enable manufacturers to create extremely fine 3D electronic structures–such as circuits, sensors, antennas and interconnects–with features as small as 10 microns using nanoparticle inks. The machines are used widely in the Aerospace and Defense, Energy, Medical Device, Advanced Electronics Packaging and Research segment.

“We are pleased to be showcasing our latest production print solutions at RAPID this year.” said Mike Dean, VP of Marketing at Optomec. “On both sides of business–printed metal and printed electronics–we have been innovating in the base print technology at the heart of the additive machine. Both the LDH 3.1, which began shipping recently, and the Endurance print head, which we are just announcing, were developed in response to our production customers who are looking for robust AM processes that are easy to integrate into their operations.”

Optomec

Optomec has a rapidly expanding, profitable Additive Manufacturing system business. It is privately owned and has a high profit margin. Optomec’s patented Aerosol Jet Systems for printed electronics, and LENS and Huffman brand 3D Printers for metal component production and repair, are used by industry to reduce product cost and improve performance. Together, these unique solutions are capable of printing a broad spectrum of functional materials – from electronic inks to structural steels and biological matter. Optomec delivered over 600 of its Additive Manufacturing Systems to more than 200 customers worldwide, for production purposes in the electronics and energy industries, as well as the life sciences, aerospace, and the life sciences. GE and Samsung are just a few of the blue-chip manufacturers that we have as customers. We also work with the US Air Force (US Navy), US Army, US Navy and NASA. Visit optomec.com for more information.

View the source version at businesswire.com https://www.businesswire.com/news/home/20230502005991/en/