Krill Design on 3D Printing Furniture Using Oranges, Lemons and Coffee Grounds

As the subject of sustainability continues to develop in significance, 3D printing is more and more on the middle of the controversy about greener manufacturing. One instance of this comes from a probably shocking supply. Krill Design’s initiatives might actually be proof that 3D printing and planet go hand in hand. The startup was based by three college students from Milan Polytechnic and now prints lamps, journal racks and ornamental objects in your house with supplies created from recycled meals reminiscent of oranges, lemons and occasional. We interviewed them to study extra!

3DN: May you introduce your self and inform us extra about Krill Design?

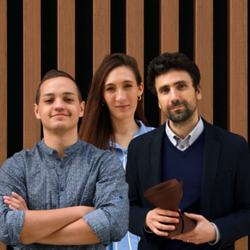

The Krill Design group (picture credit: acube).

We’re Krill Design, an revolutionary startup born in Milan in 2018. We make 3D printed design merchandise with biomaterials developed from recovered meals waste as a substitute of plastic. Krill Design was born from a gathering of three individuals united by totally different values, innovation, sustainability and design: Ivan Calimani, Martina Lamperti and Yack di Maio. The pondering of the three founders is kind of easy: there are already a number of channels that intercept and valorize waste from the manufacturing of paper, glass and plastic, whereas for the natural by-products of the meals chain, there aren’t any appropriate options. The three founders turned this drawback into a possibility by experimenting with the creation of revolutionary supplies that, mixed with 3D printing, resulted in a profitable and environmentally pleasant manufacturing course of.

3DN: Why did you resolve to make use of 3D printing?

3D printing was already well-known by of the founders, Yack and Martina, who had beforehand established a 3D printing middle. Furthermore, additive manufacturing permits us to be much more digital and sustainable. We manufacture our merchandise on demand with out creating massive inventories in case of unsold merchandise. As well as, 3D printing permits us to make merchandise customizable and to always experiment internally.

3DN: How are your 100% pure and compostable Rekrill® supplies produced?

Rekrill® is the fabric we developed in-house. We select meals waste from meals and beverage firms. The method is similar for any kind of waste: we dry it, finely chop it till it’s micronized and compound it with a 100% vegetable materials that offers the fabric its technical properties. The granulate obtained is then heated and extruded into filament by a machine. The coils are then put in on the molds.

The Rekrill® Orange materials

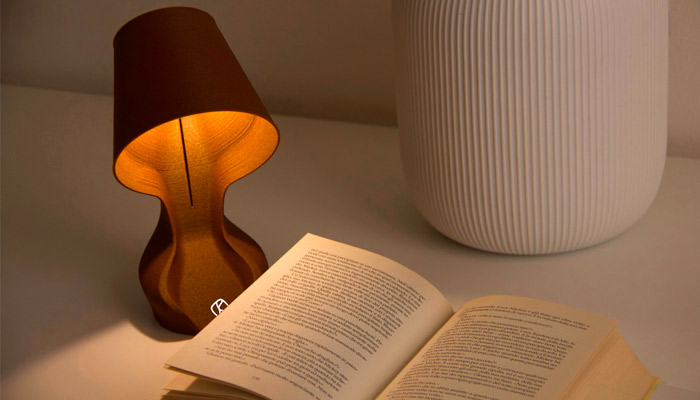

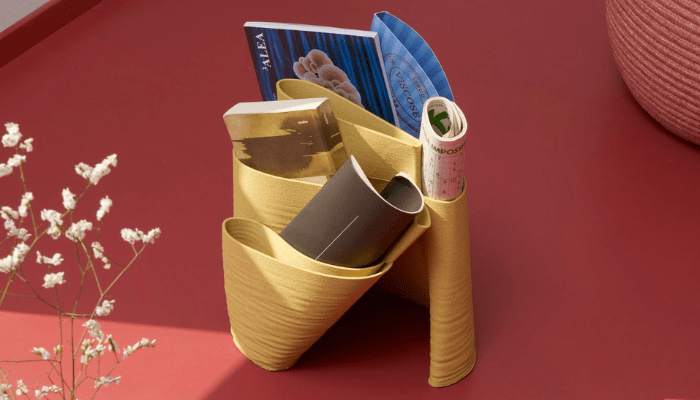

The fabric we print with is 100% biodegradable and compostable whereas nonetheless being designed to final. This and all our different merchandise don’t instantly degrade as you may suppose. Our Rekrill® supplies are available in three differing kinds: Orange, Lemon and Espresso, created from recycled orange peel, lemon peel and occasional grounds respectively. That is how our three collections of 3D printed house décor objects had been born: Ribera, Amalfi and Napoli. Ohmie, our 3D printed lamp created from orange peels, is considered one of Krill Design’s most profitable items. We’re engaged on new biomaterials for 2023.

La lampada Ohmie.

3DN: What 3D printing know-how do you employ to create your merchandise?

We use FDM know-how, which permits us to efficiently reuse waste. We have now commonplace Prusa printers and a modified Creality CR10 Max. Our Ohmie lamp is produced in about 3 hours and the journal rack in 5 hours. One of many challenges we confronted was discovering the right configuration of fabric for every product.

This incense holder was printed with Rekrill® Espresso materials

3DN: How do you see the longer term growth of Krill Design ?

Along with client merchandise, we additionally take part in round financial system initiatives with firms which have meals waste and with whom we design advert hoc merchandise from their waste. As talked about earlier, 3D printing permits us to enter the world of digital manufacturing facilities with out creating greater than obligatory. Sooner or later, we see Krill Design hubs scattered world wide to get nearer to the tip buyer utilizing native supplies.

Krill Design’s 3D printed journal rack created from recycled lemon peels

3DN: Any final phrases for our readers?

Our imaginative and prescient is definitely summarized: “Feed the change, form the longer term! Be happy to go to our web site HERE if you need extra info.

What do you consider Krill Design’s 3D printed objects and their developed supplies developed? Tell us in a remark beneath or on our Linkedin, Fb, and Twitter pages! Don’t overlook to enroll in our free weekly Publication right here, the newest 3D printing information straight to your inbox! It’s also possible to discover all our movies on our YouTube channel.

*All Photograph Credit: Krill Design