The Lumia X1 Is Overcoming Limitations in Resin 3D Printing With an Innovative Hybrid Process

Since stereolithography (the first additive manufacturing technology) was invented in early 80’s, resin 3D printers have always had a place in this sector. A number of variations are available, but DLP & SLA are the most popular. But it is difficult to know which option to select. SLA is incredibly precise and allows for extremely detailed parts. However, the laser used to cure each point makes it slow. DLP is fast, but it does not provide the same level of accuracy. What if both technologies could be combined, eliminating the limitations so that users can just enjoy the benefits. Axtra3D made it possible. The Lumia X1 has a 3D printer that uses a hybrid photosynthesis (HPS) process, which combines DLP with SLA for a more efficient resin 3D-printing.

Axtra3D is not something we’ve told you before. Gianni Zitelli founded the startup in 2021. It is located in Charlotte, North Carolina, and Vicenza in Italy. Axtra3D, with its innovative Hybrid PhotoSynthesis technology (HPS), and TruLayer technology, hopes to open up a whole new world of possibilities in the 3D printing market. The company promises a large build surface, high-resolution and fast speeds as well as impressive surface quality. In line with the company’s values, it is also committed in keeping the Lumia X1 fully open, both from a material and parameter perspective. This gives users more freedom. The company also intends to change the status quo of field service, with a 24/7 response to support requests within 60 seconds and the use AR technology to quickly resolve many issues. But what exactly can you expect from the company’s first solution, the Lumia X1?

Lumia X1 combines SLA and DLP into a hybrid process.

Using a single process to combine speed and accuracy

Undoubtedly, the Lumia X1’s 3D-printing technology is one of its main advantages. It is well-known that choosing between resin technologies can be difficult due to their many tradeoffs, namely precision and speed. HPS has made this problem a thing in the past. The lightweight engine technology combines DLP and SLA into one coaxial system.

It is a technology that integrates an image generator with a laser. The two light sources work together synchronously at the exact same wavelength, with the same plane of the image. The image generator cures the bulk of the cross-section, or “Flash Hatching.” This allows for the speed of DLP. The laser also creates the border contours to improve surface quality with a 50 micron resolution. Axtra3D, according to their own words, has been able to: “unlock unparalleled print speed, quality and accuracy.” It is also possible to scale up the technology so that it can be used for larger platforms, which allows for a higher build volume, something rare with most resin 3D printer processes.

HPS isn’t the only innovation in the Lumia X1. TruLayer is another feature of the printer that, according to its manufacturer, will revolutionize resin 3D-printing. The fact that layers can adhere to the plate is a major drawback of all resin photopolymer processing. This causes delays. TruLayer was designed to solve this problem.

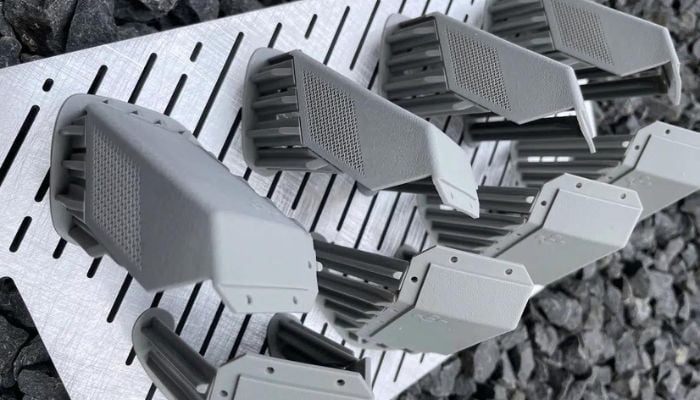

Impellers (left) on the Lumia X1 whose Build Plate is shown on right

Essentially, in the Lumia X1, Axtra3D has incorporated a trio of sensors onto the glass plate beneath the printer’s membrane, thus eradicating inter-delays while amplifying the printing speed twofold. How? This innovation allows the print layer to be quickly detached from the vat, thus removing the restrictions on the size and bulk of the sections. This vat membrane now has a long-lasting quality, and can print even viscous resins.

Paul Spolianksy CRO at Axtra3D explains in more detail “Since implementing our TruLayer Technology, we’ve noticed a significant performance advantage over our competitors. We’re excited to provide our customers with top-notch resolution, unmatched accuracy, and fast print speeds that not only enhance production applications but also make them economically viable.”

Lumia X1: Additional Features

Lumia X1’s 3D Printer is not only attractive because it integrates TruLayer Technology and Hybrid Photosynthesis, but also for its other unique features. The solution, which is built to industrial standards and has a 10-year working life, will be able to withstand the test of time. It also offers several safety features, including ventilation, magnetic interlock, UV-shielded viewing windows, and an emergency stop button. The Intelli-Cartridge is also included, as well as a double Z-Axis and an integrated 4k camera chamber. It has a large graphic interface, and it can be used in both online and offline modes.

Lumia X1 parts can be produced quickly and accurately.

Intelli-Cartridge is a particularly exciting innovation, according to the company. The Intelli-Cartridge aims to automate and simplify the 3D printing by managing the resin by dispensing the material into the vat, collecting excess material and stirring as well as heating and filtering. Intelli-Cartridges also allow for an increase in the total amount of resin available for printing to 8 liters, and eliminate the need for manual topping-up.

It also reduces waste by removing extra resin and filtering it before returning it to cartridge. The Intelli-Cartridge also ensures consistency in material levels in each layer, while infrared heating controls the temperature. The feature is a key factor in improving efficiency and convenience for high-volume printing. These are factors that are evident in the Lumia X1 overall. If you would like to learn more about the Axtra3D and the Lumia X1 3D printer, you can go to Axtra3D’s website HERE or their LinkedIn HERE.

What do think of Axtra3D’s Lumia X1 3-D printer? Please let us know by leaving a comment on this page or our The following are some of the most recent LinkedIn posts:, Facebook. Twitter pages! Don’t forget to sign up for our free weekly Newsletter HereGet the latest 3D Printing news delivered to your mailbox! Our videos can be found on our YouTube channel.

*All Photo Credits: Axtra3D