Revolutionizing Energy Absorption with 3D-Printed Structures

Robotics and AI Result in Breakthroughs in Materials Deformation

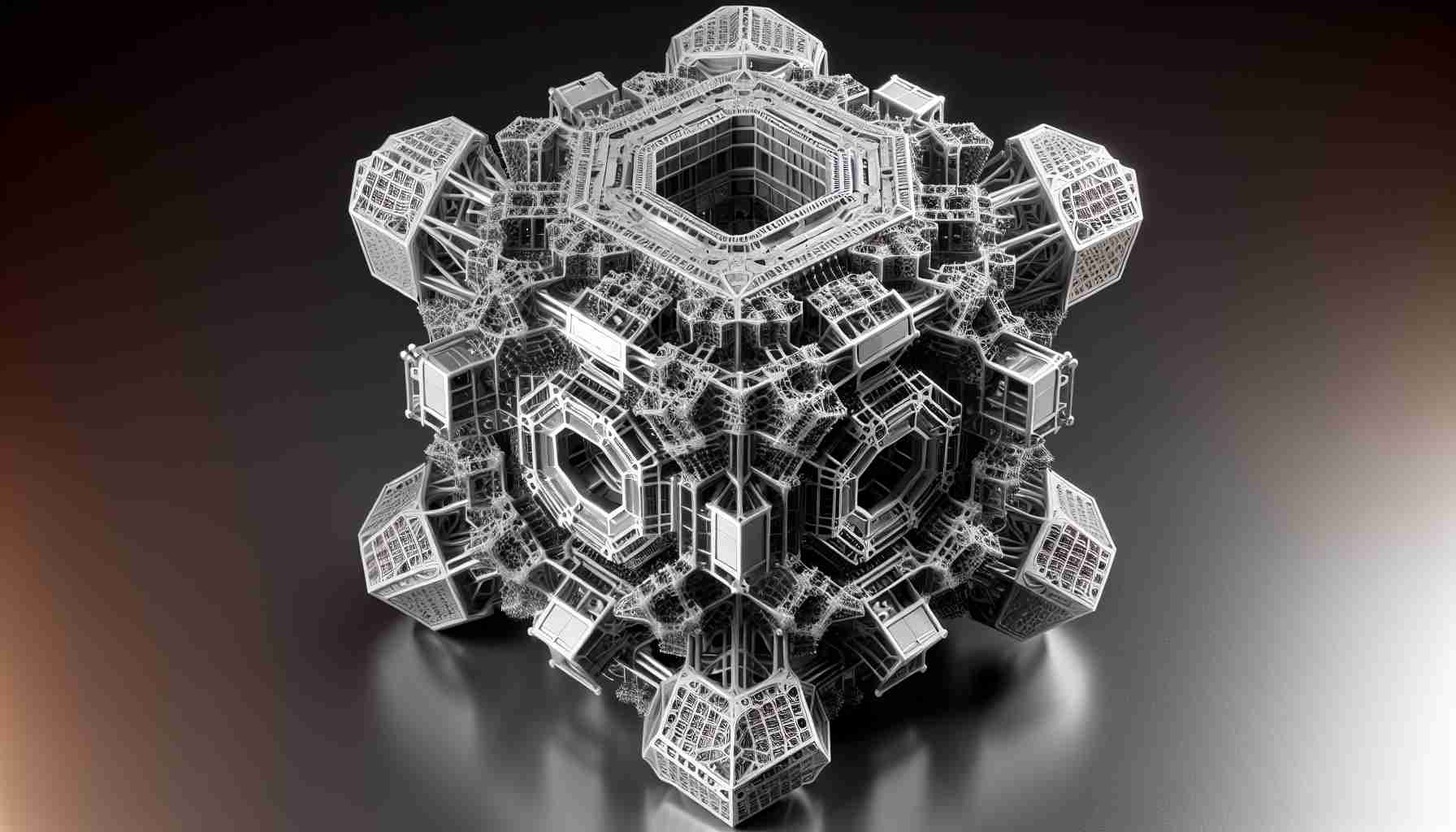

Boston College has set a benchmark within the subject of fabric science with its modern challenge named MAMA BEAR, an acronym that stands for Mechanics of Additively Manufactured Architectures Bayesian Experimental Autonomous Researcher. This tireless machine, pushed by refined AI, has been tirelessly experimenting with completely different shapes to find one that may soak up mechanical vitality most successfully by means of deformation.

Using a set of 5 3D printers, MAMA BEAR repetitively prints and destroys small cylindrical buildings made of assorted supplies, together with TPU, nylon, PETG, and PLA. Every printed object is then weighed and transported by a robotic arm to a urgent machine that simulates the drive equal to that of an Arabian thoroughbred horse.

State-of-the-art sensors and cameras meticulously report the deformation of the construction, permitting the autonomous system to tweak and enhance the form parameters for subsequent prints. The aim is to search out the optimum type that may finest soak up exterior drive by means of its personal deformation.

Surpassing Human-Designed Vitality Absorption Constructions

MAMA BEar has managed to outperform human-crafted designs, which had peaked at 71% deformation effectivity. By persevering with to study and refine, this method has surpassed the 75% threshold, showcasing its findings within the esteemed journal Nature.

This analysis paves the best way for the event of unprecedented buildings able to effectively absorbing vitality, which might revolutionize security options in varied purposes. From vehicle fenders to different vitality dissipating zones, these supplies goal to guard essential parts and, most significantly, human lives by dissipating kinetic vitality by means of managed destruction. This exceptional improve in effectivity implies that the vitality left to break something behind such deformation zones – like a automotive’s engine or the motive force – is considerably decreased, marking a major step ahead in protecting materials design.

Exploring the Significance of Superior Vitality Absorption

3D-printed buildings designed for vitality absorption are essential for a variety of industries, together with automotive, aerospace, protecting gear, and even area exploration. The know-how being developed by Boston College might have a major impression on the design of supplies that want to face up to impacts, crashes, or different varieties of forceful occasions. In spacecraft, for instance, such supplies could possibly be used to dampen shocks and defend delicate devices throughout launch, touchdown, or unexpected impacts with area particles.

Essential Questions and Solutions:

– What’s 3D printing and the way does it relate to this breakthrough?

3D printing, or additive manufacturing, is a course of of making bodily objects from digital designs by layering materials. This know-how is on the core of the breakthrough, because it permits for fast prototyping and iteration of complicated buildings which may then be examined for his or her vitality absorption capabilities.

– Why is AI integration essential on this analysis?

AI integration permits the autonomous analysis and adaptation of structural designs, resulting in a extra environment friendly optimization course of than standard guide strategies. By incorporating AI, the training and enchancment cycle is considerably expedited, leading to a possible for locating superior designs that is perhaps inconceivable for human-engineers to conceive.

– How may these 3D-printed buildings change the way forward for security designs?

Improved vitality absorption buildings can significantly improve the security of automobiles, buildings, tools, and protecting wearables by minimizing the drive transmitted to people or delicate parts upon impression, thus lowering the chance of harm or tools harm.

Key Challenges and Controversies:

– Making certain the scalability and manufacturability of those designs for mass manufacturing is essential. It stays to be seen how these buildings might be built-in into present manufacturing methods and the way cost-effective they are going to be on a bigger scale.

– Materials efficiency over time and beneath completely different environmental situations is a priority for long-term reliability. Additional analysis is required to find out how these buildings will behave beneath extended stress, temperature variations, or publicity to chemical compounds and different components.

– There may also be mental property and patent considerations relating to the distinctive designs produced by AI, which might result in authorized and moral debates in regards to the possession of AI-generated content material.

Benefits and Disadvantages:

– Benefits:

– The power to create complicated buildings that surpass human design limitations.

– Sooner iteration and optimization of designs because of AI integration.

– Potential for elevated security and safety in varied purposes.

– Personalised and customizable buildings might be produced to suit particular necessities.

– Disadvantages:

– The preliminary price of analysis and improvement for such superior methods might be excessive.

– Complexity within the integration of those new supplies into present manufacturing and product traces.

– Uncertainty in regards to the long-term sturdiness and environmental impression of those supplies.

– Potential mental property points surrounding AI-generated designs.

For these involved in exploring extra about additive manufacturing and the way forward for supplies science, you possibly can go to web sites similar to:

– Nature for scientific analysis articles and breakthroughs within the subject.

– Boston College to study extra about their numerous analysis initiatives and contributions to materials science.

– Worldwide Group for Standardization (ISO) for requirements and laws associated to additive manufacturing and its supplies.