Researchers use 3D-printing technique to produce smart AR contact lens

[Courtesy of UNIST]

SEOUL — A group of researchers has used a particular 3D printing method to provide a sensible contact lens for augmented and digital actuality. The handy and environment friendly manufacturing method supplies the next probability of commercialization for the modern contact lens.

3D printing makes use of particular filaments which are molten earlier than they’re sprayed layer over layer to create the ultimate form. The filaments might be made of various supplies that can harden when cooled. Because of 3D printers’ potential to make use of totally different filaments concurrently, particular printing strategies are actually utilized in numerous industries together with the meals processing, semiconductor manufacturing, and building industries.

To actualize digital actuality (VR) or augmented actuality (AR), head-mounted-display (HMD)-type headsets are most generally used. Nonetheless, such gadgets are cumbersome and really costly for bizarre shoppers. Good contact lenses are virtually as mild as a feather and don’t limit physique actions. Additionally, they are often distributed at inexpensive costs when they’re mass-produced.

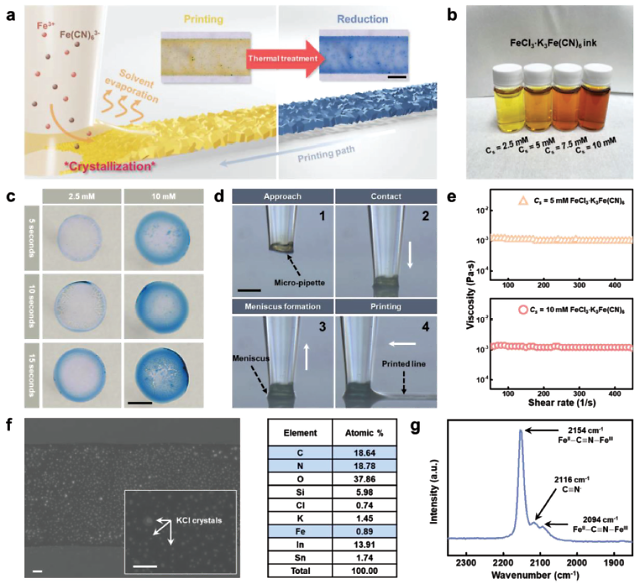

The Ulsan Nationwide Institute of Science and Know-how (UNIST) mentioned that researchers from the institute and the Korea Electrotechnology Analysis Institute (KERI) cooperated to develop a 3D-printed sensible lens for VR and AR. The lens makes use of electrochromic show expertise to be operated at a really low-voltage degree. The high-definition 3D-printing method was used to print micro-patterns onto the lens’ show. Prussian blue, a darkish blue pigment produced by the oxidation of ferrous ferrocyanide salts, was used as the fabric for patterns.

In accordance with UNIST, the sensible lens is predicted to be extensively used within the navigation sector. Utilizing the electrochromic show, the lens was in a position to present its wearer an AR-based navigation map. “We count on this analysis will obtain a number of consideration from battery and biosensor firms which want Prussian blue-based micropatterning method in addition to firms from the AR trade,” UNIST researcher Jeong Im-doo mentioned in a press release on February 6.

© Aju Enterprise Every day & www.ajunews.com Copyright: All supplies on this web site is probably not reproduced, distributed, transmitted, displayed, printed or broadcast with out the authorization from the Aju Information Company.