Researchers create stable hybrid laser by 3D printing micro-optics onto fibers

For the primary time, researchers have proven that 3D-printed polymer-based micro-optics can stand up to the warmth and energy ranges that happen inside a laser. The advance allows cheap, compact, and steady laser sources that may be helpful in a wide range of functions, together with the lidar programs used for autonomous automobiles.

“We considerably diminished the scale of a laser through the use of 3D printing to manufacture high-quality micro-optics straight on glass fibers used inside lasers,” mentioned analysis group chief Simon Angstenberger from the 4th Physics Institute on the College of Stuttgart in Germany. “That is the primary implementation of such 3D-printed optics in a real-world laser, highlighting their excessive injury threshold and stability.”

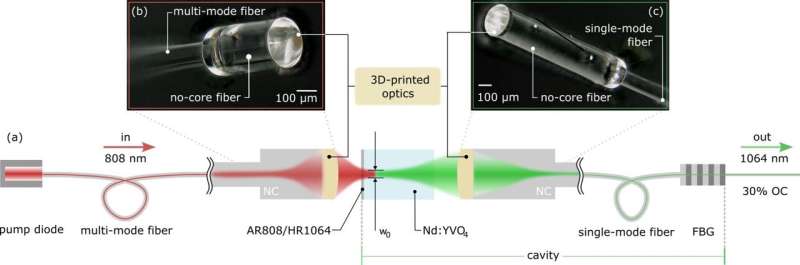

Within the journal Optics Letters, the researchers describe how they 3D printed microscale optics straight onto optical fibers to mix fibers and laser crystals inside a single laser oscillator in a compact approach. The ensuing hybrid laser exhibited steady operation at output powers of over 20 mW at 1063.4 nm and had a most output energy of 37 mW.

The brand new laser combines the compactness, robustness, and low price of fiber-based lasers with the benefits of crystal-based solid-state lasers, which might have a broad vary of properties comparable to completely different powers and colours.

“Till now, 3D-printed optics have primarily been used for low-power functions comparable to endoscopy,” mentioned Angstenberger. “The power to make use of them with high-power functions could possibly be helpful for lithography and laser marking, for instance. We confirmed that these 3D micro-optics printed onto fibers can be utilized to focus giant quantities of sunshine all the way down to a single level, which could possibly be helpful for medical functions comparable to exactly destroying cancerous tissue.”

Taking the warmth

The 4th Physics Institute on the College of Stuttgart has a protracted historical past of creating 3D-printed micro-optics, particularly the power to print them straight on fibers. They use a 3D printing strategy generally known as two-photon polymerization, which focuses an infrared laser right into a UV-sensitive photoresist.

Within the laser’s focal area, two infrared photons will probably be absorbed concurrently, which hardens the UV resistance. Transferring the main target round permits numerous shapes to be created with excessive precision. This technique use can be utilized to create miniaturized optics and likewise permits novel functionalities such because the creation of free-form optics or advanced lens programs.

“As a result of these 3D-printed parts are product of polymers, it was unclear whether or not they might stand up to the numerous quantity of warmth load and optical energy that happens inside a laser cavity,” mentioned Angstenberger. “We discovered that they’re surprisingly steady, and we weren’t capable of observe any type of injury on the lenses even after a number of hours of operating the laser.”

For the brand new examine, the researchers used a 3D printer made by Nanoscribe to manufacture lenses with a 0.25 mm diameter and peak of 80 microns onto the top of a fiber with the identical diameter utilizing two-photon polymerization.

This concerned designing an optical aspect with industrial software program, inserting the fiber into the 3D printer, after which printing the small construction on the top of the fiber. This course of have to be extraordinarily exact when it comes to aligning the printing to the fiber and the accuracy of the printing itself.

Making a hybrid laser

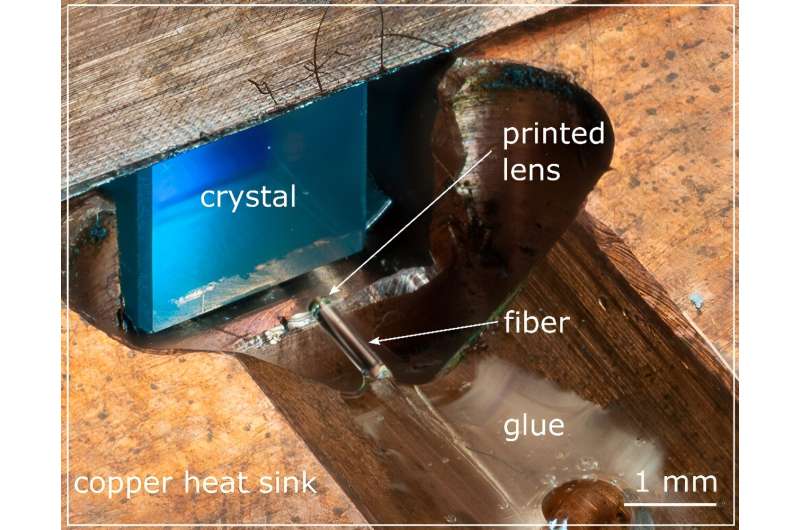

After the printing was full, the researchers assembled the laser and the laser cavity. Reasonably than utilizing a crystal inside a laser cavity product of cumbersome and dear mirrors, they used fibers to kind a part of the cavity, making a hybrid fiber-crystal laser. The lenses printed on the finish of the fibers focus and acquire—or couple—the sunshine into and out of the laser crystal.

They then glued the fibers right into a mount to make the laser system extra steady and fewer vulnerable to air turbulence. The crystal and the printed lenses measured simply 5 X 5 cm2.

Constantly recording the laser energy over a number of hours verified that the printed optics contained in the system didn’t deteriorate or have an effect on the long-term properties of the laser. Moreover, scanning electron microscopy pictures of the optics after use within the laser cavity didn’t present any seen injury. “Curiously, we discovered that the printed optics had been extra steady than the industrial fiber Bragg grating we used, which ended up limiting our most energy,” mentioned Angstenberger.

The researchers are actually working to optimize the effectivity of the printed optics. Bigger fibers with optimized freeform and aspherical lens designs or a mix of lenses printed straight onto the fiber might assist enhance the output energy. They might additionally wish to show completely different crystals within the laser, which might permit the output to be custom-made for particular functions.

Extra info:

Simon Angstenberger et al, Hybrid fiber–solid-state laser with 3D-printed intracavity lenses, Optics Letters (2023). DOI: 10.1364/OL.504940

Quotation:

Researchers create steady hybrid laser by 3D printing micro-optics onto fibers (2023, December 13)

retrieved 13 December 2023

from https://phys.org/information/2023-12-stable-hybrid-laser-3d-micro-optics.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.