Manufacturing high-resolution transformable 3D structures

Have you imagined high-resolution 3-D structures at the nano/microscale that respond dynamically to their surrounding? Smart materials, which exhibit shape deformation when exposed to external stimuli are used in 4D printing. This technology has enormous potential in fields such as biomedicine, flexible electronic, soft robotics and aerospace.

There’s still a big challenge to overcome: in order for 4D printing technologies to be able print features as small as sub-micrometers or smaller, they need higher resolution.

A publication in the International Journal of Extreme Manufacturing, Prof. Qi Ge’s team from Southern University of Science and Technology introduces a game-changer— Two-photon polymerization-based (TTP-based) 4D printing technology, which can fabricate high-resolution, ranging from 90 nm to 500 nm, and transformable 3D structures at the micro/nanoscale.

This paper summarizes the latest advancements in the TPP-based technology of 4D printing and its applications. It begins by explaining technological advances of TPP-based printing, defining its working principle as well as recent progress.

The review also highlights how smart materials are being used for TPP based 4D Printing. The paper also highlights the essential applications of TPP based 4D Printing, such as biomedical microrobots.

Bingcong Jian was the first to publish the paper. “TPP technology empowers fabrication of multifunctional Micro/Nanostructures, by selecting appropriate photoresists tailored to the functions of the targeted application.”

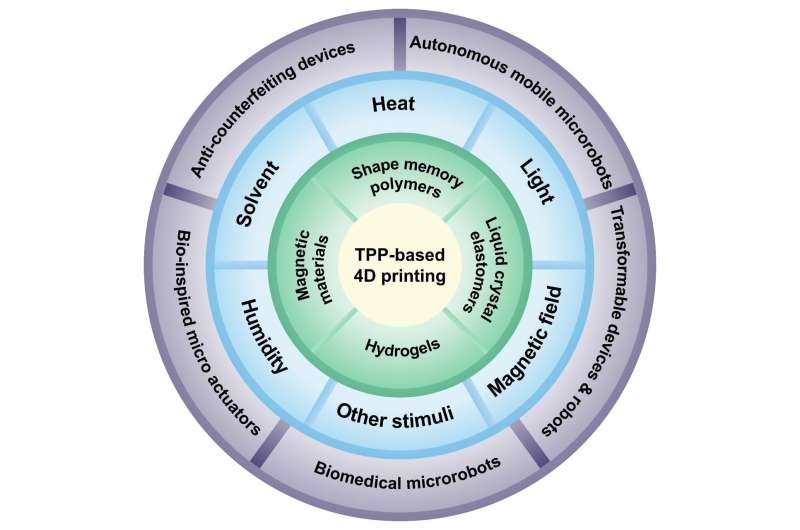

These specialized photoresists are able to create micro/nanostructures that exhibit dynamic properties like stimulus responsiveness, biomimetic auto-actuation and color-changing capabilities. Commercial photoresists cannot achieve these properties. Four categories of 4D printing materials are available for TPP: magnetic materials (including shape memory polymers), hydrogels and liquid crystal elastomers.

The 4D process involves a program that transforms the 3D structure into a new shape, material, or functionality. It is capable of morphing shapes, multi-functionality and self-assembly. It is time-dependent, printer-independent, and programmable. The advent of TPP based 4D Printing technology promises to revolutionize many fields in the near-future, including biomedicine, robotics, and nanotechnology.

The applications can be classified according to structural changes and evolutions, such as color changing, locomotion, shape morphing or state switching. The potential applications of TPP based 4D printed structure can be classified into five categories, including biomedical micromachines (micromachines for medical purposes), bioinspired microactuators (microactuators that mimic biological processes), autonomous mobile microrobots (microrobots with autonomy), transformable devices and robotics, and anticounterfeiting Microdevices.

Qi Ge says, “As we continue to explore 4D printing based on TPP, we face both fascinating challenges and exciting excitement.” “Our future involves addressing the challenges we face with an emphasis on innovation and adaptation.

“It’s important to increase our manufacturing capacity. We need to develop equipment capable at handling different materials on a micro/nanoscale. This will make TPP-based 3D printing a staple in diverse industries. It is a journey towards greater print speed, precision, and scalability. Our quest to optimize the material’s performance is equally important. We are only as good as the photoresists.

“To achieve structural changes and functional excellence, it is essential that we innovate and refine photoresists which have superior chemical, mechanical, and thermal attributes. These materials should be durable, flexible and robust. Our design methodology is at the core of all our future efforts. We are exploring how to integrate process, material and structure into a harmonious framework.

“This approach utilizes topological optimizing and machine learning simultaneously to refine the print process, material choice, and structural designs. This allows for the creation of micro/nanostructures that have tailored functionality.

“Our goal is clear. We aim to open up new possibilities in TPP-based 3D printing by using advanced design techniques. In order to overcome these challenges, we need to do more than just advance technology. We also have to reshape industries and develop innovative applications. “We’re thrilled to begin this journey, as we chart the future for TPP-based 4-D printing.”

For more information, please visit:

Bingcong Jian et. al., Two-photon-polymerization-based 4-D printing and its Applications. International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acfc03

Provided by

International Journal of Extreme Manufacturing

Citation:

Micro/nanoscale 3D Printing Revolution: Manufacturing high-resolution, transformable structures (2023 October 11).

Retrieved on 11 October 2023

from https://phys.org/news/2023-10-micronanoscale-4d-revolution-high-resolution-3d.html

This document is protected by copyright. This document is protected by copyright.

No part of the website may be reproduced or copied without written permission. This content is only provided as information.