Isar Aerospace relies on the nebumind software to automatically identify defects of metal 3D printed parts

With hundreds of layer photos to research when trying to find errors, it’s straightforward to overlook a essential defect that can consequence within the non-validation of an element. The actual fact is the powder recoating performed after every printed layer is vulnerable to error: If the floor to be uncovered isn’t coated evenly and utterly, this could result in defects within the element.

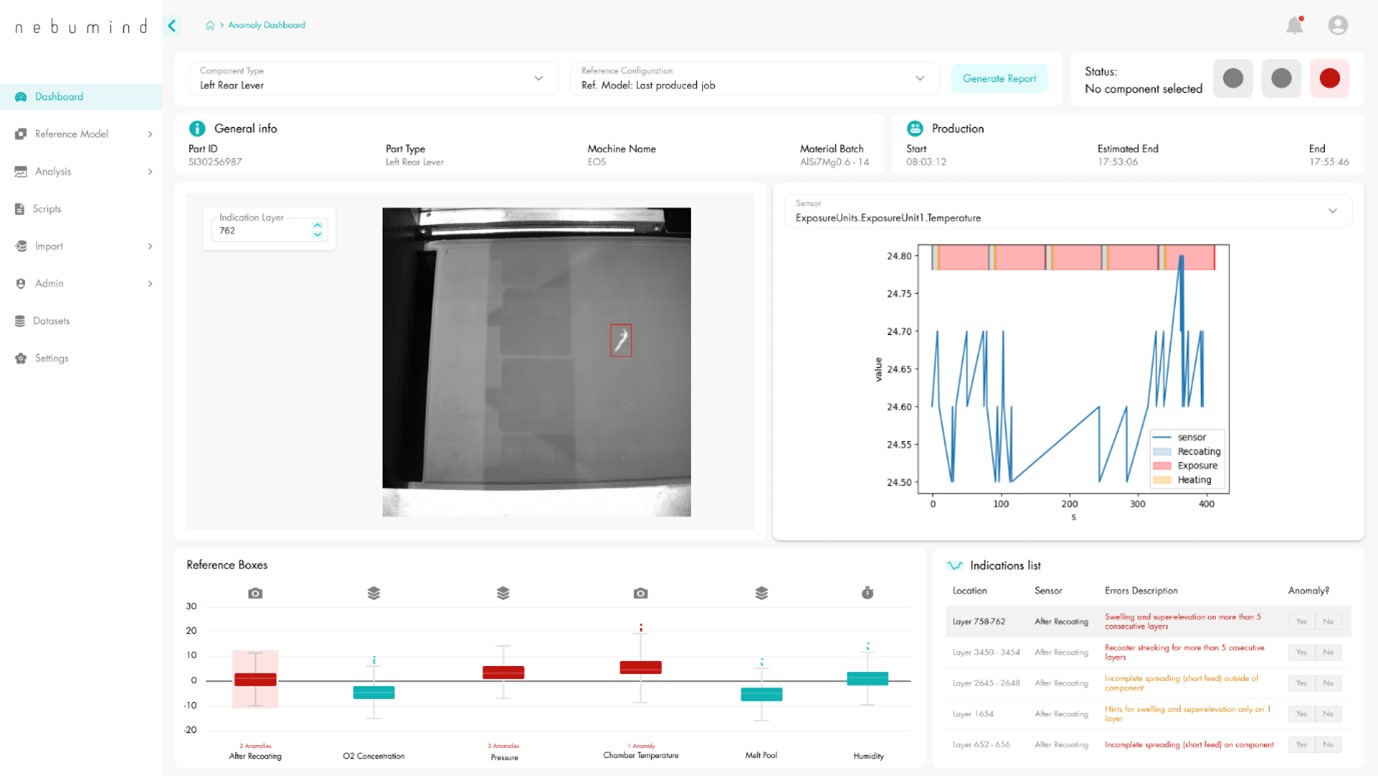

To handle this resolution, AM customers more and more flip to automated software program options that might assist them do the job throughout the 3D printing course of. It’s the case of aerospace firm Isar Aerospace that just lately built-in the nebumind software program into its 3D printing course of (LPBF – Laser Powder Mattress Fusion) to automate the identification and reporting of defects throughout the software of a brand new powder layer.

The corporate of the identical title is predicated in Germany and develops analytics software program shops and visualizes manufacturing knowledge as digital product twins. Its software program detects defects by automated evaluation of the powder mattress photos, offering the engineer with essential info for evaluating the standard of the printing course of.

The issue with the handbook evaluation of recoater photos

The issue is easy: sensors and cameras built-in into the L-PBF techniques monitor the coating step, which might be manually analyzed for uncoated areas, injury to the recoater or different defects by engineers liable for the method. This method is extraordinarily time-consuming: as an example, if a 3D printed steel element generates 2,500 recoater photos and an engineer takes 3 seconds to research every picture, they spend greater than 2 hours on this activity for one construct job alone. Furthermore, because the evaluation is performed in a post-processing step, defects are often solely recognized after a element has been printed.

nebumind automates picture evaluation and presents defects in-process in digital twin format

To forestall this handbook course of, Isar Aerospace has linked the nebumind software program into its machine surroundings automating the defect detection for every recoating layer. The software program receives powder mattress photos earlier than and after recoating, generated by an optical digicam with a decision of 1280×1024 pixels, and extracts them routinely by way of the direct machine interface. The software program makes use of an algorithm to identify defects within the photos routinely. For its algorithm, nebumind has employed primarily secure algorithms from picture and edge detection. As well as, the positions of the defects are analyzed throughout a number of layers to reduce the false constructive fee.

In line with nebumind, Isar Aerospace has been in a position to save as much as 80% utilizing its software program in comparison with the earlier handbook evaluation, as engineers can concentrate on the photographs labeled by the algorithm.

Learn extra concerning the identification of defects throughout the steel 3D printing course of.

Shifting ahead, nebumind’s defect recognition will probably be moved upstream from post- printing to in-process, in order that the software program will be capable to level out doable anomalies instantly after coating, thereby enabling the consumer to cease the printing course of within the occasion of an irreparable defect. To additional automate the method, it’s deliberate to correlate the discovered recoater defects with different course of knowledge from the print job and CT knowledge from the ultimate high quality examine to determine root causes and stop recoater defects from taking place within the first place. In the long run, nebumind not solely needs to observe the printing course of with its software program, but in addition to intervene within the course of in a regulating method, for instance to cease the printing course of within the occasion of irreparable errors or to compensate for an incorrect coating within the subsequent layer, the corporate explains.

Keep in mind, you’ll be able to put up job alternatives within the AM Trade on 3D ADEPT Media at no cost or search for a job by way of our job board. Be sure that to observe us on our social networks and subscribe to our weekly e-newsletter: Fb, Twitter, LinkedIn & Instagram ! If you wish to be featured within the subsequent situation of our digital journal or when you hear a narrative that must be heard, ensure you ship it to [email protected]