Hot off the press: Wide-format printing trends for businesses to follow

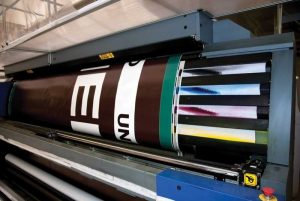

Propelled by new ideas and applications, the wide-format printing market has experienced significant growth. Photo © Moreno Soppelsa | Dreamstime.com

Aditya Bhardwaj and Sohil Singh

The emergence of innovative ideas and new applications has fueled significant growth in the wide-format printing market. Wide-format printing is becoming more popular in other industries than just advertising. Customers also demand more customized solutions in digital print offerings. This opens up a new market for print service provider (PSPs), which can expand and diversify existing portfolios. What follows is a look at today’s trends in digital wide-format printing, as well as how PSPs can take advantage of their growing presence in the market.

Soft signage and textile printing

Many applications have found texture to be a desirable alternative to visual display. Recently, texture has emerged through textile display elements like soft signage. Now, it is moving on to more rigid substrates. Wood-grain texture is gaining more popularity in a variety of substrates, including expanded polyvinyl chloride (PVC) signboard, as it is application-friendly, durable, and visually appealing. You can create an image using large-format flatbed printers. They can also be used to create engraved structures that double as signage and can withstand the elements for many decades.

The architecture industry is seeing the benefits of using wide-format printing and varied textured substrates to customize interiors or exteriors in building projects—think rustic lodge interiors with custom-imaged components, such as wayfinding, or structural or signage-related common room elements.

Another area that continues to have an impact on visual communications is textile printing. Customers are keen to see specialty applications in this market, regardless of whether it’s soft signage, direct–to-garment or direct–to-textile. They also appreciate the quick turnaround times that these applications offer. Even though print companies strive to reduce turnaround times, customers will still want customized and personal options.

Trends are also emerging in the supply chain to support direct-to fabric printing, especially soft signage. The industry is changing the way print buyers view point-of-purchase signage. This includes equipment manufacturers, ink producers, and fabric suppliers. All aspects of textile-based printing—from decor to fashion—will continue to grow exponentially, as these applications create new opportunities to generate revenue for print providers and new product options

Customers

Print service providers (PSPs), today, are offering newer printing technologies, such as UV (direct-to-substrate) printing and expanded digital finishing capabilities. These technologies offer the possibility to explore new revenue streams. Images courtesy Stratojet USA

New printing technologies:

PSPs today are using newer printing technologies such as UV (direct-to-substrate) printing and expanded digital finishing capabilities. There are more options than ever to explore prototype and short-run packaging as potential revenue streams. Many companies that produce signage and graphics have the opportunity to offer and distribute the applications their customers need. There is a growing demand for packaging that can be customized and printed in shorter runs. This is a great opportunity for PSPs with experience in short runs and fast turnarounds. They can empower small and large businesses to address their packaging needs at a more localized, unique level.

With the right finishing capabilities and wide-format equipment, printers have the potential to create promotional short-run packaging. Because of their long lead times and expensive equipment, promotional short-run packaging is difficult for printers to compete in. Local manufacturers will offer new opportunities to printers who are experts in this field. This market is growing and can be used by wide-format printers.

It is expected that the inks will continue to change as technology and market demand evolve. Many companies have begun to expand beyond traditional four-colour printing and include spot colours that can be used in any metal or neon. These new inks can deliver eye-catching, distinctive splashes with colour and will allow for greater colour fidelity.