Defining SROI: Examples, Part 2

This text is a component of a bigger sequence on Sustainability Return On Funding (or SROI) and needs to be learn within the order:

What’s SROI, and why do we’d like it?

Getting ready For Transparency With A Versatile Worth Chain, Backed By Information

Defining The ‘How’ And The ‘What’ Of SROI – Half 1

On this, the second half in our give attention to defining what a Sustainability Return On Funding (SROI) appears like, we need to present 4 distinct examples, every comparable to a course of taken from every of the 1 – 4 tiers of the availability chain. From a model’s perspective, these examples correspond intently to real-world challenges and situations, and all are areas wherein client and regulatory scrutiny is excessive, which means that the potential return on making a measurable enchancment is any of them is excessive.

First, although, some statistics for context. Everyone knows the style trade generates colossal waste points, contributing to an estimated 8% of world greenhouse gases. How can we deal with such a big challenge? The reply is ‘one piece at a time’. For instance, let’s give attention to the normal sample-making course of, which makes use of appreciable assets to generate giant portions of discarded bodily samples and is, by any definition, not sustainable.

Style Tech Week 2023 and Attire Useful resource supporting statistics from the present conventional sample-making course of that emphasises the alternatives to enhance each sustainability and the underside line;

• The style trade presently spends USD$ 6-8 billion on bodily sample-making per 12 months.

• Over 30% of supplies are wasted through the seven phases of sample-making for a single piece of clothes.

• Most bodily samples go on to storage and finally to a landfill.

• If manufacturers and factories created just one bodily pattern for each garment fashion presently manufactured, they would cut back the sample-making value by USD$ 4.5-6 billion.

We’d like to inform you tips on how to take away all bodily samples and waste from ‘unselected’ prototype types and ship the USD$ 4.5-6 billion financial savings estimated above, however that’s unrealistic. In spite of everything, designing, prototyping, and manufacturing stays an iterative, analogue course of that’s nearly by no means “proper first time”.

The style trade has already begun the sustainability enchancment journey, and it’s simply getting ‘critical’. Nevertheless, this shall be a decades-long journey if we ever full and attain 100% sustainable practices.

The examples beneath will not be a ‘silver bullet’, however merely sensible examples of candidates for sustainability enchancment initiatives. Every firm should put together their instruments, map provide chain processes, acquire related major knowledge and prioritise the sustainability initiatives to execute for its enterprise primarily based by itself SROI evaluation of every initiative.

Utilizing IoT to assist enhance irrigation practices

If we examine the water required to develop cotton, we discover that one kilogram of standard cotton requires 10K-20K litres of water to supply.

And if we checklist the highest International cotton producers throughout 2022, we see the large quantity of water used to develop these cotton crops.

That’s as much as 420 billion litres, or 420 million m3 (cubic metres) of water used to develop cotton in these 8 international locations. It’s additionally vital to notice that the majority cotton is grown in international locations already dealing with water stress, making this useful resource utilisation particularly unsustainable at each a humanitarian and environmental stage.

Increased Cotton Yields with Much less Water

At the moment, farmers are beginning to implement pc imaginative and prescient and IoT applied sciences (Web of Issues) to assist map their fields, measuring soil moisture through IoT units to alert farmers to the place water is required to make sure wholesome crops and on the similar time, guarantee they aren’t over-watering areas with the dear useful resource. These IoT units supported by AI/ML (Synthetic Intelligence & Machine Studying) assist farmers to ship precision-targeted watering. Several types of irrigation programs for cotton manufacturing; floor irrigation, sprinkler irrigation and drip irrigation programs. Every of those programs can utilise IoT units to handle the water provide in probably the most environment friendly method; examples would come with watering throughout darkness to forestall the evaporation of water from the soil. The most recent irrigation pattern is a drip system the place tubes run beneath the floor of a subject, giving water on to the crop’s root zone.

Initiatives such because the Higher Cotton Stewardship have produced vital outcomes displaying that Higher Cottom Farmers in 4 international locations have used much less water for the irrigation of cotton than Comparability Farmers, starting from 6% much less in Tajikistan to 13% much less in India. For instance, suppose we use the price of a cubic metre (m3 / 1,000 litres / 1 kiloliter) of water in Maharashtra of $0.92. In that case, we discover {that a} 13% potential saving of as much as 16 million m3 of this valuable useful resource utilized throughout India would additionally save a money worth of USD$14.6M.

Digital dyeing of Thread and Yarn

Digital dyeing of thread and yarn helps on-demand manufacturing runs and sampling wants, producing vital sustainability advantages, with considerably lowered power, 90% water discount on common, and little or no waste supplies, plus improved velocity to market, the accuracy of color matching, and high quality.

• No MOQs (minimal order portions) and materials waste linked to DTM (dyed to matched) order necessities.

• JIT (Simply-In-Time) on-demand manufacturing dyeing and sampling wants.

• Dramatic discount in set-up time and power assets linked to conventional dyeing strategies.

• Tremendously lowered inventory and value of supplies utilizing a typical greige thread/yarn.

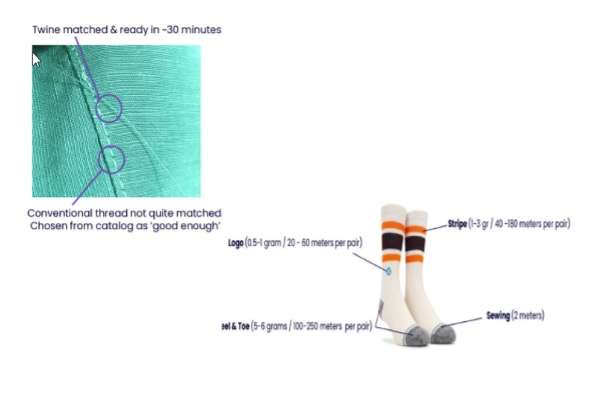

If we think about sewn small garment orders and sampling, thread in an actual color match is important. Comparable applies to yarns utilized in knitted merchandise. Manufacturers’ and retailers’ time constraints require the ‘nearest’ catalogue color, however usually, and color matching isn’t adequate; the method completes a number of cycle iterations earlier than remaining approval.

Situation

The important thing challenge is matching the designers’ seasonal colors with a restricted inventory of thread/yarn catalogue colors. A number of obstacles come up when a thread/yarn with a brand new DTM color commonplace is required. The moist dye course of requires a lead time of round 7-12 days to ship the pattern thread/yarns. On common, the thread MOQ is commonly 40 km (kilometres), in comparison with a pattern requirement of 1-2kms. This ends in the potential waste of 38kms of thread, or 95% of the order if the colourway will not be chosen.

The identical challenge applies to restricted yarn colors in inventory. Moreover, a number of sections in socks usually require a number of yarn DTM colors. The yarn waste for one part of a sock ranges from 30% for manufacturing runs to 99% for sampling when a couple of grams of yarn are required, however MOQ is 1kg. The waste multiplies when a number of yarns in a single sock fashion require a brand new color commonplace. Like threads, the moist dye course of for yarns requires a minimal lead time of round seven days or extra, plus a delivery length. For manufacturing, yarn(s) shall be over-ordered as a contingency, resulting in extra stock.

Moist dyeing waste for 10 pairs of pattern socks & 2,800 pairs of batch manufacturing

Course of change

Adopting digital dyeing expertise, utilizing greige undyed threads/yarns to ship DTM (Dyed-To- Matched) supplies that, in flip, can be utilized to ship On-Demand (PLM, Invoice of Supplies) orders, and ‘exacting’ sampling necessities. Greige inventory threads will be dyed in any color commonplace, with 1-2 kilometres of pattern threads produced in 30 – 60 minutes.

Small orders of clothes, socks (round 3,000 pairs), luggage, footwear, equipment, and associated soft-sewn textiles or knitted merchandise will be made out there for delivery inside 2-3 days.

Advantages

Along with the listed enhancements, a reputational enhancement is linked to the improved high quality of service supplied. Timelines for uncooked supplies with new DTM colors are lowered by over 80% on common. The digitally dyed supplies will be out there inside 30mins onsite. If delivery is required, factories and knitters can cut back their lead instances from 7-12 days to 2-4 days.

Utilizing greige thread/yarn dramatically reduces a manufacturing unit or knitter’s inventory ranges and waste by avoiding MOQs, saving greater than six thread cones per color. Avoiding the moist dyeing course of allows a >90% discount in water utilization and effluent creation, and a >90% discount in Co2 equal greenhouse gasoline emissions.

We have now been made conscious of On-demand manufacturing and sampling lead instances lowered by 30-70%. Digitally dyed pattern yarns will be out there inside 1-3 days in comparison with a minimal of seven days for moist dye processing, excluding delivery. The digital dyeing course of allows a >90% discount in water utilization and effluent creation and a >50% discount in Co2 emissions.

You’ll be able to study extra about digital thread and yarn dyeing right here.

Conventional Cloth Printing vs Digital Cloth Printing

When designing printed materials, there are constraints when contemplating the normal material printing course of. The foundation of those points is the price and time required to create the totally different screens for a number of color separations. Price might constrain the designer to a most of three or 4 colors per print, and there shall be a median 3-month lead time for bulk printed materials.

Moist dyeing points and effectivity limitations

The normal printing course of ‘effectivity threshold’ is round 1000 items, with the effectivity of power and water use bettering as volumes enhance. Above 5000 items per print run, the waste produced per merchandise is dramatically lowered. Nevertheless, as the typical trade order dimension decreases, the variety of print runs above 1000 items, by no means thoughts 5000 items, per run is reducing.

When balancing constraints vs effectivity in conventional wet-dye printing, the ‘effectivity’ facet of the ledger doesn’t prevail till there are giant unit numbers per print run. Due to this fact, a extra environment friendly and cost-effective various to conventional printing is required for small manufacturing orders and all print sampling.

Firms are creating compelling advantages circumstances for digital printing. Because the Direct To Garment (DTG) and Direct To Roll (DTR) set up base continues to extend, and the expertise is highway examined and confirmed to be steady, there are extra use circumstances for Print On Demand creating in conventional retail. A number of components are driving this curiosity.

- Pace to market – The power to design a brand new print and make it prepared on the market in days somewhat than weeks or months is an actual recreation changer.

- Low MOQs – Eradicating the restrictions of MOQs makes the ordering course of so much simpler.

- Sustainability – Lowering waste by solely printing to fulfil the precise order, leading to fewer merchandise in landfills.

- Lowering water utilization – Direct To Textile (DTT) is a waterless course of, eradicating the gallons of water it takes to prep a display screen for printing.

- Diminished carbon footprint – Producing and delivery from the closest level to order supply.

- Danger-averse – Eradicating danger from the idea and design course of. With DTG, color is just restricted by RGB. You’ll be able to design with whole freedom and will not be constrained by the variety of colors your producer can produce.

- Check new markets – Strive a brand new market with little or no danger, which is probably not your core buyer.

- Diminished inventory holding – Working your enterprise 100% on demand is now doable by benefiting from the deep plain inventory out there and the ‘JIT‘ (Simply in Time) precept.

Sure, digital printing machines, on the face of it, seem costly. Nonetheless, loads of digital printing service bureaux supply this functionality, and if you measure the ‘true advantages,’ you would possibly discover that the worth of the machine outweighs the price.

Classes discovered from mills’ efforts to cut back greenhouse gases

Like each associate enterprise working within the style provide chain, mills work onerous to realize sustainability objectives. Some have lowered their power assets, carried out water purification tasks, and put in photo voltaic panels, spending six-figure sums which have helped transition 50-60% of their electrical energy to renewables, linked to SROI paybacks estimated in 3-5 years.

Nevertheless, it has been found that tasks of this nature to enhance sustainability for the excessive power processes required by mills and moist dye processes have restricted influence on GHG emissions, many solely leading to single-digit reductions.

For these processes, a big component of emissions is derived from the era of warmth. To attain double-digit emission reductions, mills might want to give attention to decreasing warmth wastage, reminiscent of various power era from various gas sources and environment friendly heating programs, with the most effective power recycling and repurposing capabilities and IoT controls to make sure constant power utilization.

This demonstrates the holistic strategy that have to be taken to search out the most effective resolution for the precise course of to allow administration and mitigation of ecological influence.

Design-By-Influence – is a brand new software program device that enables model or retail designers to make use of course of knowledge to mannequin a garment assembled with the supplies and totally different manufacturing companions. On this situation, a number of T1 factories might every use various kinds of equipment, or electrical energy consumption will differ and be charged at one other worth primarily based on the nation’s electrical energy (wattage) fees. Then you definately would possibly need to think about the manufacturing unit effectivity ranges, truthful labour charges, to not point out the kind of transport (Air vs Sea) and miles/kilometres distance from the manufacturing unit to the model’s warehouse and finally right down to the shop location(s).

Design-to-impact instruments will permit designers and builders to go deeper; for instance, Absolutely Factored (liable for acquiring and testing of supplies, elements & trims) vs CMT (lower, make & trim), finally every could have totally different prices of assets and transportation that in flip will influence the general sustainability scores.

The ability of course of breakdown mixed with major knowledge

As we have now mentioned, probably the most vital enhancements in environmental influence and development to the underside line is knowing the results of all processes.

Let’s think about the stitching operations in a CMT manufacturing unit. Every stitching operation entails a number of stitching machine varieties, every with totally different stitching motors and totally different apps/wattage. This provides to probably vital power utilization variations throughout factories. This variation has an influence on CO2e Kg and value.

For instance, if we assume the wattage of all machines used to fabricate a garment in 2 factories is identical, and we used the printed common $/kWh for companies in June 2022, we see variations between neighbouring international locations.

• China is ~22% costlier than Indonesia or Vietnam.

• Pakistan is 25% costlier than India and 45% extra expensive than Bangladesh.

• India is 16% costlier than Bangladesh.

• Mexico is 42% costlier than the USA.

• Nicaragua is 14% costlier than Guatemala.

• Honduras is 29% costlier than Nicaragua.

Moreover, if we thought-about textile mills in Europe, utilizing the identical printed common $/kWh for companies in June 2022;

• Italy is 178% costlier than Spain.

These examples are a tiny component of the big amount of processes and first knowledge that could possibly be leveraged to offer our groups within the digital worth chain with choices for extra sustainable and worthwhile merchandise by knowledgeable selections.

Design-By-Influence instruments

The style trade wants the instruments to seize the first knowledge and supply a easy and efficient consumer interface to your group to check processes and consider choices.

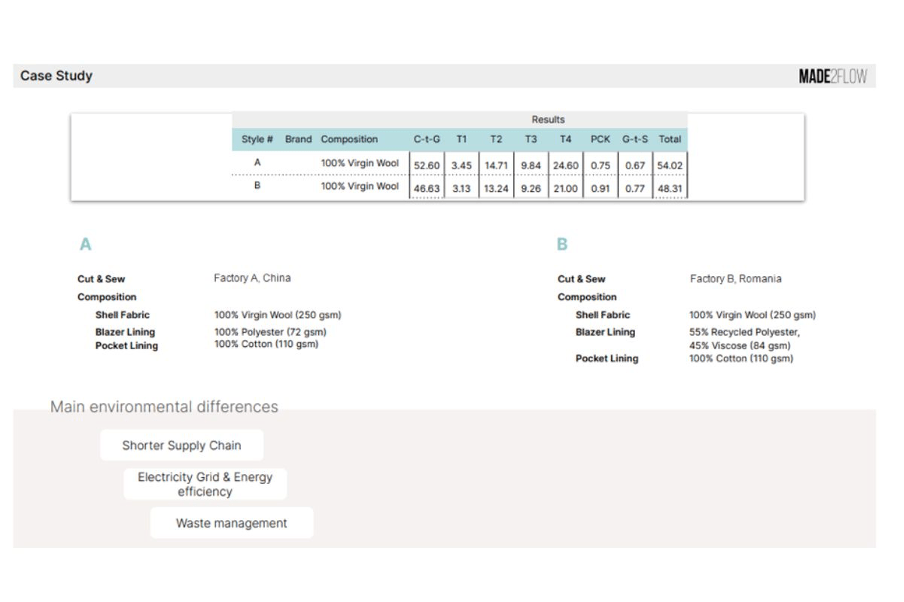

The instance beneath is a GHG Design-By-Influence device that compares GHG influence for 2 provide chains. The information instance applies to a swimsuit with three linings, utilizing the identical material provider in Italy, two various CMT factories (China and Romania), separate packaging, and Gate to Website (G-t-S) to the identical warehouse in New Jersey through sea freight.

The CO2e Kg is calculated utilizing Main knowledge collected from all related provide chain processes and is summarised for every of the Tiers 1-4 plus Packaging (PCK), the Cumulative to Gate (C-t-G) quantity for all of the Tiers and Packaging, Gate to Website (G-t-S) delivery, and the overall for the delivered product.

Comparability for every of those processing teams is supplied, with insights into the environmental variations between the 2 variations of the availability chain. It turns into simple to establish the ecological advantages between 2 choices, whether or not they’re totally different areas with the identical processes, totally different styling on the identical product, or you’re figuring out enhancements between processes. The group would mix this GHG knowledge with different major knowledge, reminiscent of value, truthful wage, timescales and different ESG knowledge, to make the ultimate knowledgeable choice.

Design-By-Influence offers the group with the environmental ‘information’ of every possibility, or equally, to allow your undertaking group to evaluate, prioritise and validate setting course of enchancment in a phased strategy. Considered one of many instruments that captures an component of major knowledge and offers insights to assist make an knowledgeable choice. There is a gigantic alternative to mix all these insights to offer holistic insights to energy the style trade into a brand new period of sustainability.

Conclusion

An unlimited depth of data is embedded within the style trade provide chains. The work to extract and leverage this major knowledge is huge and isn’t one thing one firm can do independently.

Specialist corporations are main the science-based assortment and evaluation of trusted major knowledge. The style trade should act to work collectively to agree on all of the variations of major knowledge and create options to contribute to the holistic view of chosen provide chains.

The excellent news is that options will be leveraged to allow compliance with the approaching legalisation. As well as, the identical instruments can be utilized to enhance earnings and substantiate sustainability credentials. Nevertheless, the clock is ticking, and corporations must make a transfer earlier than they’re pressured to take action.

Authors: Mark Harrop & Chris Jones