Creating Highly Conductive Metallic Gel for 3D Printing

The Researchers Have Developed a Highly Conductive Metallic Gel that Can Be Used to Print 3D Solid Objects at Room Temperature.

“3D printing has revolutionized manufacturing, but we’re not aware of previous technologies that allowed you to print 3D metal objects at room temperature in a single step,” says Michael Dickey, co-corresponding author of a paper on the work and the Camille & Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University. “This opens the door to manufacturing a wide range of electronic components and devices.”

The researchers begin by creating a suspension of copper microns in water. The researchers add a small quantity of an indium/gallium alloy, which is liquid metal when at room temperatures. The mixture is then mixed together.

As the mixture is stirred, the liquid metal and copper particles essentially stick to each other, forming a metallic gel “network” within the aqueous solution.

“This gel-like consistency is important, because it means you have a fairly uniform distribution of copper particles throughout the material,” Dickey says. “This does two things. The network of particles will connect to create electrical pathways. And second, it means that the copper particles aren’t settling out of solution and clogging the printer.”

The gel produced can be used to print using a 3D printing nozzle. When printed, the gel retains its form. The resulting 3D objects become more solid when dried at room temperatures.

If the user decides to heat up the object as it dries, interesting things can occur.

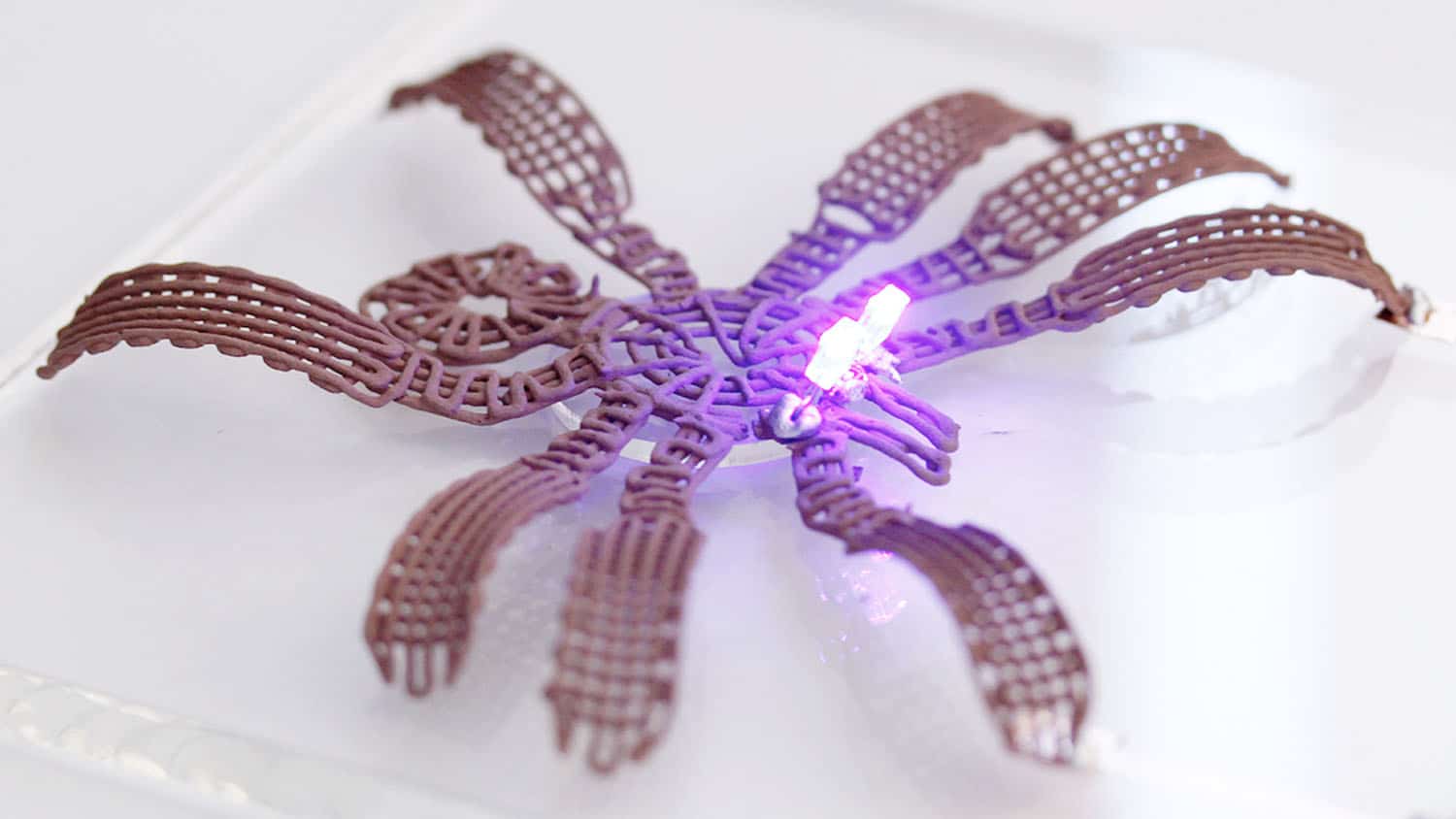

Researchers found that alignment of particles affects how material dries. As an example, if a cylinder was printed, the sides of the object would shrink more than the tops and bottoms as it dried. If something is drying at room temperature, the process is sufficiently slow that it doesn’t create structural change in the object. However, if you apply heat – for example, put it under a heat lamp at 80 degrees Celsius – the rapid drying can cause structural deformation. This deformation can be controlled because it is predictable. You can change the shape of a printed object by changing the pattern and how much heat is applied to the object during drying. Video of the metallic gel printing and drying process can be found at https://youtu.be/xFxo1Ah8EAc.

“Ultimately, this sort of four-dimensional printing – the traditional three dimensions, plus time – is one more tool that can be used to create structures with the desired dimensions,” Dickey says. “But what we find most exciting about this material is its conductivity.

“Because the printed objects end up being as much as 97.5% metal, they are highly conductive. It’s obviously not as conductive as conventional copper wire, but it’s impossible to 3D print copper wire at room temperature. And what we’ve developed is far more conductive than anything else that can be printed. We’re pretty excited about the applications here.

“We’re open to working with industry partners to explore potential applications, and are always happy to talk with potential collaborators about future directions for research,” Dickey says.

The paper, “Metallic Gels for Conductive 3D and 4D Printing,” is published in the journal The Matter. First author of the paper is Ruizhe Xing, a former visiting scholar at NC State who is affiliated with Northwestern Polytechnical University and Tianjin University. Co-corresponding authors of the paper are Dickey, at NC State, and Renliang Huang and Wei Qi of Tianjin University. The paper was co-authored by Jiayi Yang, a former visiting scholar at NC State, now at Xi’an University of Science and Technology; Dongguang Zhang, a former visiting scholar at NC State, now at Taiyuan University of Technology; Wei Gong, a former visiting scholar at NC State, now at the National University of Singapore; Taylor Neumann, a former Ph.D. student at NC State; Meixiang Wang, a postdoctoral researcher at NC State; and Jie Kong of Northwestern Polytechnical University.

The National Natural Science Foundation of China and the China Scholarship Council provided funding for this work.

-shipman-

Editors’ Note: Here is the abstract.

“Metallic Gels for Conductive 3D and 4D Printing”

Authors: Ruizhe Xing, North Carolina State University, Northwestern Polytechnical University (China) and Tianjin University; Jiayi Yang, North Carolina State University and Xi’an University of Science and Technology; Dongguang Zhang, North Carolina State University and Taiyuan University of Technology; Wei Gong, North Carolina State University and National University of Singapore; Taylor V. Neumann, Meixiang Wang and and Michael D. Dickey, North Carolina State University; Renliang Huang and Wei Qi, Tianjin University; and Jie Kong, Northwestern Polytechnical University (China)

PublishedJuly 5, The Matter

DOI: 10.1016/j.matt.2023.06.015

Abstract: This paper reports printable metal gels (pendular suspendeds) consisting aqueous suspensions containing copper (Cu) particle bridged by liquid eutectic Gallium Indium alloy (EGaIn). Pendular suspensions rely on capillary forces to form networks between solid particles with a composition-dependent rheology, but prior studies have focused on insulating suspensions. By adjusting the pH, we can tune the rheology for 3D-printing. The dry printed parts have metallic electrical conductivity (1.05×105 S/m), without the need for sintering. The drying process at high temperatures can speed up the removal of moisture while creating stress which drives shape changes (i.e. 4D printing). In order to demonstrate this, we printed a conductive web that builds its body by lifting and assembling a flat form. These conductive inks can be used to print metallic structures under ambient conditions.

Original Article: How to create highly conductive metallic gel for 3D printers

The new gel material filters clean water for daily needs

Adventures in Nanotech – Growing a Metallic Snowflake

Colloidal Gels aren’t like Glass