Additive Assurance Talks Ensuring Part Quality in Metal 3D Printing

Metallic additive manufacturing is being utilized by many superior industries because of the power to create advanced and customised elements. Nevertheless, to make sure feasibility and high quality, it’s important to validate the elements obtained. That is a necessary step to keep away from defects and guarantee optimum efficiency. In flip, certifications be sure that specs and mechanical properties are constant in every manufacturing batch, offering confidence to finish customers. Thanks to those processes, customers are assured of the standard, sturdiness and reliability of elements, facilitating their integration into numerous functions, from medical and aerospace to automotive and industrial sectors. This contributes to the consolidation of metallic additive manufacturing as a viable choice in Business 4.0. One of many corporations on the forefront of this know-how is Additive Assurance, with its AMiRIS resolution. We spoke with its founders to be taught extra about their exercise.

3DN: May you introduce your self and inform us your connection to 3D printing?

I’m Marten Jurg, an additive manufacturing engineer and CEO of Additive Assurance. With my co-founder Andrey Molotnikov, we began Additive Assurance to resolve what we noticed as crucial limitation in 3D printing: half repeatability and consistency. We’ve been pushing the boundaries of metallic additive manufacturing for greater than a decade. I began working in additive manufacturing (AM) by way of analysis R&D tasks for aerospace techniques integrators, and later took on tasks in different sectors, equivalent to vitality and medical units. From this expertise, qualification and certification have at all times been very a lot within the forefront. Whereas it’s nice to have the ability to manufacture advanced geometries, if you happen to can’t certify them to be used, they’re ineffective.

Additive Assurance co-founders Marten Jurg (left) and Andrey Molotnikov (proper).

Once we began, we had been investigating the fatigue properties of L-PBF elements for aerospace functions, the place the influence of stochastic defects can create a major discount partially design life, and the potential of AM designs. We noticed that the stochastic nature of AM drove up prices and posed a barrier to adoption. We realized that if we might guarantee half consistency by way of inspection, we might assist scale back prices and unlock large-scale manufacturing.

3DN: What’s Additive Assurance? How did it come about?

Additive Assurance is a supplier of high quality assurance options for metallic laser powder mattress fusion (L-PBF) techniques. The genesis of Additive Assurance dates again to my PhD with Andrey at Monash College. On the time, we had been engaged on the fatigue of AM elements made with L-PBF, and had been confronted first hand with the inconsistency points that come up on this course of. Like many others, we had been utilizing CT scanning to detect defects in fabricated elements. CT scanning is sluggish, costly and was a serious bottleneck.

The issues we had been observing within the course of piqued our curiosity for on-site monitoring in 2016. We noticed the wealth of knowledge out there by way of statement of soften emissions, nevertheless, present techniques actually suffered from two essential drawbacks: the quantity of information generated and the shortage of research. By means of experimentation with varied detection modalities, we developed what would grow to be AMiRIS, a high-resolution, long-exposure near-infrared monitoring approach that may very well be simply tailored to any L-PBF machine. The high-resolution meltpool pictures had been wealthy intimately, and their format allowed us to develop a machine studying method to find defects the place they occurred.

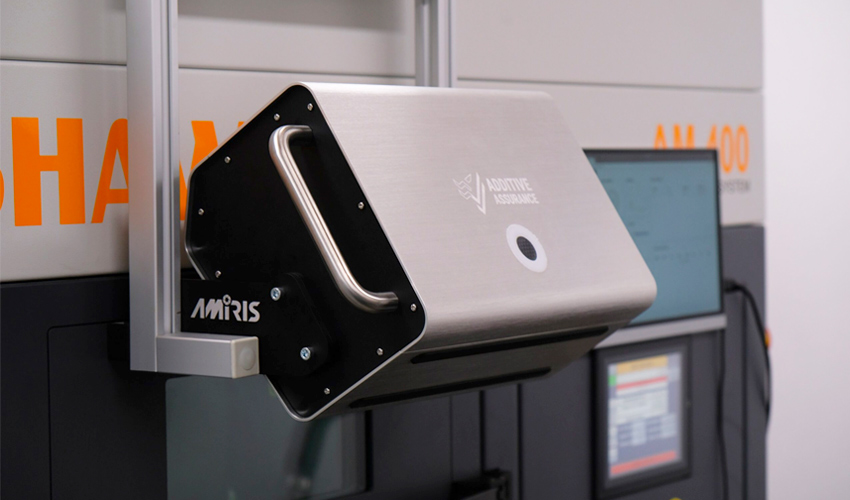

Photograph Credit: Additive Assurance

We additionally noticed issues within the complexity of the opposite options out there and the problem of putting in them on machines, requiring important downtime for set up and voiding the producer’s guarantee. Finish customers additionally don’t know what to do with the mountains of knowledge they produce, leading to different points equivalent to information storage and discovering time to translate what all of it means. We labored with our improvement companions and prospects to resolve these issues.

3DN: What’s AMiRIS and what’s its function within the additive manufacturing course of?

AMiRIS is a high quality management sensor suite for all L-PBF techniques, unbiased of machine provider. It makes use of close to infrared sensors mixed with machine studying methods to determine defects and anomalies with micron accuracy. ML fashions enable customers to find and determine faults routinely. Thus, they will cease defective constructions, saving money and time. However most significantly, they supply proof of building conformance, the idea for half certification.

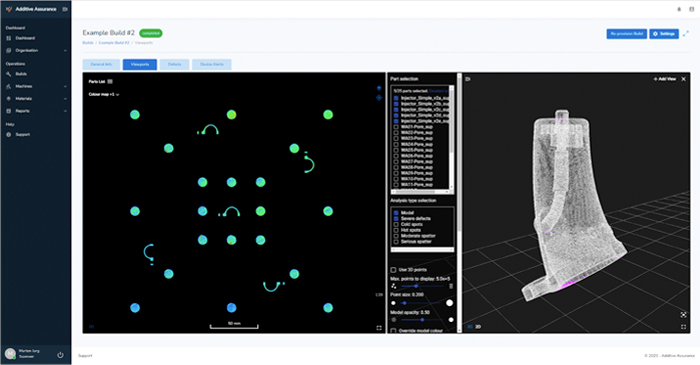

The AMiRIS platform is out there as a scalable cloud-based resolution or as an area set up. Sensing models are put in on fleets of various machines and transmit the captured information to a central server, the place GPU compute cases find defects and inconsistencies. Centralizing all this info permits customers to kind a whole image of their AM operations, from half defect to machine productiveness and preventive upkeep.

The AMiRIS cloud-based platform (photograph credit: Additive Assurance)

We use machine studying analytics that mix the info stream into easy move/fail standards primarily based on user-defined limits. Machine failures, laser scanning errors, geometric variations, coater interference, course of variations, underfusion and overfusion are just some of them. AMiRIS is simple to put in, non-intrusive and might be utilized on present platforms with out interrupting work.

3DN: What benefits does the know-how supply and what markets are you focusing on?

In the case of AM, growing manufacturing and productiveness is essential to increasing our {industry}, and doing so whereas making certain high quality is crucial. We’ve labored quietly with teams within the aerospace, vitality and orthopedic gadget sectors. Our know-how will increase productiveness in these industries, with the additional advantage of traceable high quality documentation.

Many of the {industry} has needed to depend on post-process inspections, equivalent to CT scanning, which may be very time-consuming and costly for elements produced by L-PBF. Because of this, generally the manufacturing course of stops for months, solely to seek out out that the elements don’t move inspection. The consumer then goes again to the start to reprint the identical elements, doubling the price and lengthening the lead time. AMiRIS permits the consumer to see defects on elements in manufacturing, to save lots of time, cash and complications within the post-processing part. With our know-how, finish customers can anticipate to extend productiveness and scale manufacturing whereas decreasing wasted materials.

We primarily goal regulated producers within the aviation, industrial house, protection, medical and transportation markets, however have additionally discovered helpful functions in different industrial sectors. We’re at all times looking out for forward-thinking consultants keen to embark on the journey with us to drive AM into mass manufacturing globally.

The AMiRIS sensor unit mounted on a Renishaw machine (photograph credit: Additive Assurance).

3DN: What can we anticipate from Additive Assurance sooner or later?

Like different industries and superior producers, we’re on the lookout for elevated manufacturing capability. With bigger scale printers producing extra elements, we are going to see extra potential for essential defects and the necessity for industry-focused regulated options. That’s why we collaborate with producers and software program suppliers to combine our know-how into these fast-growing machines and repair extra platforms in additional areas. International enlargement is a vital precedence. As we proceed to develop and develop into different markets, we’re constructing our strategic alliances. We’re on the lookout for shiny new expertise to assist us lead on this essential subject and assist increase world requirements.

3DN: Any final phrases for the readers?

In the previous few years, the {industry} has been keen to claim itself. Lack of high quality was an impediment, however now not. Superior on-site management, evaluation for certification, certified assurance and reporting have arrived. We might like to have forward-thinking corporations, consultants and personalities be part of us on this journey or be part of our advisory board. We now have a viable resolution for certifying the standard of elements in manufacturing – that’s confidence you possibly can depend on. Yow will discover out extra in regards to the firm HERE.

What do you consider the answer developed by Additive Assurance? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly e-newsletter right here, the most recent 3D printing information straight to your inbox! You too can discover all our movies on our YouTube channel.

*Cowl Photograph Credit: Additive Assurance