3devo to cease sales of filament recycling equipment as part of new business model

On the finish of 2023 3devo, a producer of 3D printing materials processing techniques, introduced plans to vary its enterprise mannequin.

The corporate acknowledged that it has moved away from a standard gross sales mannequin, and can not instantly promote its 3D printing filament recycling know-how.

Speaking the choice to stakeholders, companions, and shoppers, 3devo described this transition as a ‘daring step’ that can ‘deepen our influence and assist’ for buyer and associate initiatives.

The netherlands-based firm has now offered readability on what this new method will appear like. 3devo CEO Tim Wesselink has highlighted that, having ceased direct gross sales of apparatus, the corporate will now supply a subscription-based “leasing mannequin” the place clients can lease tools after they want it.

The corporate may even supply assist to shoppers all through all levels of their initiatives, particularly tailoring 3devo tools to buyer wants. 3devo will proceed to supply present clients with spare elements for bought machines. What’s extra, clients will nonetheless be capable of buy {hardware} by means of 3devo’s reseller channels.

Wesselink hopes that this new method will “align buyer success with our personal success,” to allow 1 million 3D printing improvements by 2032. This new enterprise mannequin can be mentioned to be more cost effective for shoppers, mitigating the monetary dangers related to 3D printing initiatives.

Prospects will pay month-to-month or yearly for this providing, with a alternative of three completely different subscription packages – Discovery, Core Venture, and Superior.

“We imagine that we ought to be there to assist a consumer alongside the way in which, to distribute the danger and the worth evenly, as a result of there’s numerous threat that comes into play when you put money into an answer that you simply’re not utterly certain goes to get you the place you need to be,” acknowledged Wesselink within the official announcement video.

“We imagine as an organization we ought to be carrying this accountability along with our shoppers as a associate and taking steps collectively in the direction of that purpose.”

3devo’s 3D printing portfolio

Based in 2016, 3devo produces {hardware} that permits customers to recycle previous materials and create their very own 3D printing filaments.

The corporate first entered the 3D printing market with the launch of the NEXT 1.0 and Superior extruders. Each techniques enable customers to recycle undesirable 3D prints into new filament, yielding fascinating materials combos within the course of.

The corporate has since expanded its portfolio with the launch of the GP20 2-in-one Shredder Hybrid for recycling 3D printing plastics, in addition to purging supplies such because the DevoClean Midtemp EZ.

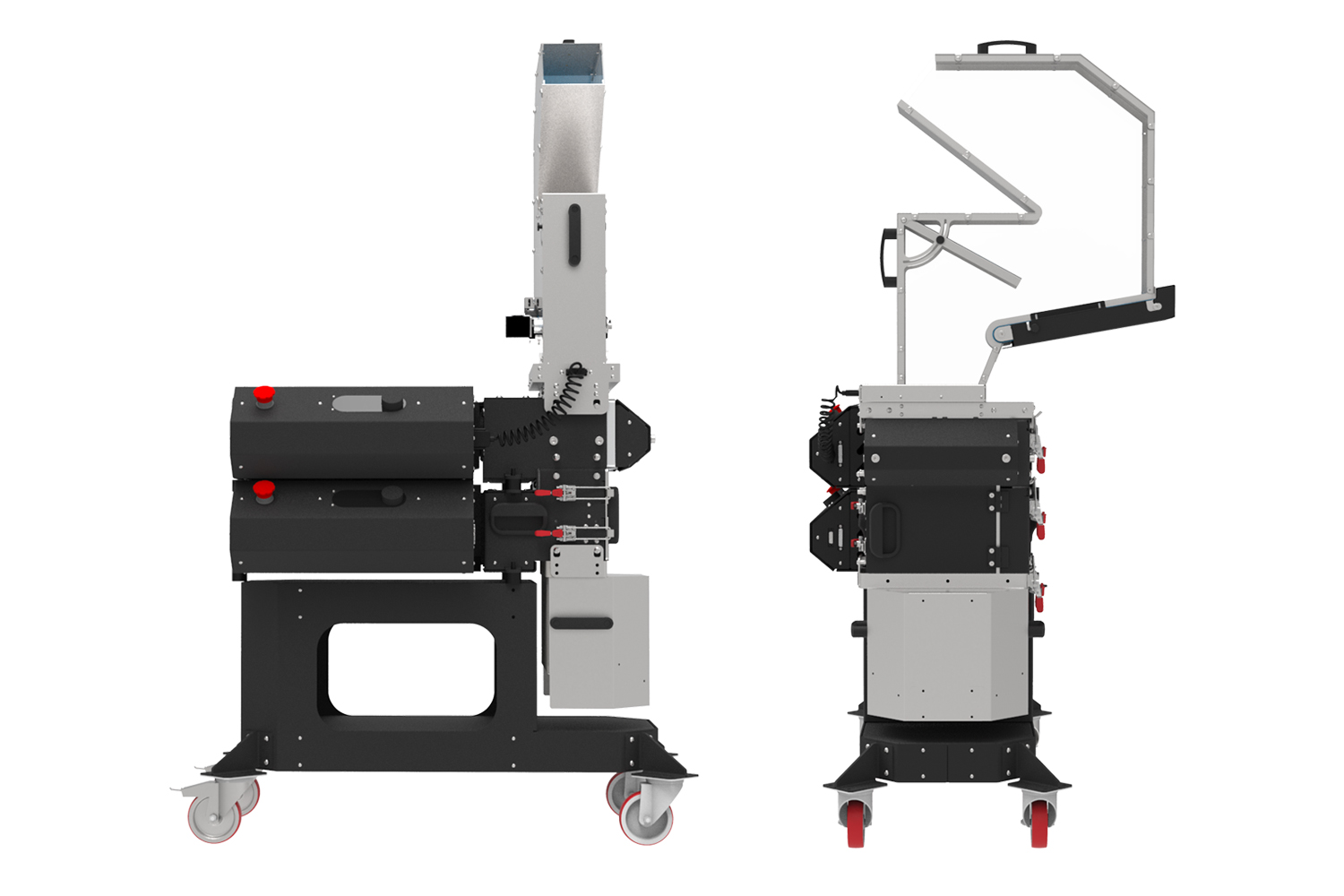

Most not too long ago, the corporate launched the Filament Maker TWO at Formnext 2023. This upgraded system integrates superior knowledge insights, improved extrusion management, precision, and stability. The Filament Maker TWO is focused in the direction of technical groups, instructional establishments, and public labs, due to its user-friendly design.

This new materials processing system is out there in two fashions – Fusion and HighFlow. The Fusion configuration is optimized for analysis and growth purposes, enabling materials mixing and the creation of customized filaments. HighFlow is designed for manufacturing purposes, offering a gentle move appropriate for compound or virgin supplies.

A brand new enterprise mannequin to align buyer success

3devo’s new enterprise mannequin features a phased method to buyer initiatives, providing shut collaboration with shoppers to make sure its know-how is nicely suited to challenge necessities. Initially, the corporate works with the consumer to guage the challenge, decide whether or not the goals are sensible, and description how greatest these targets may be achieved.

There isn’t a assure {that a} consumer’s challenge can be nicely suited to 3devo’s know-how. “We need to be very clear and candid about what is feasible for us to ship and what’s not, to ensure expectations are balanced,” defined Wesselink. This preliminary stage requires comparatively small monetary and time commitments from each side.

Subsequent, 3devo affords clients an opportunity to evaluate its {hardware} choices and decide which know-how would work greatest inside their challenge. That is achieved by means of workshops which 3devo can both maintain in-house or on-site on the consumer’s location. As soon as {hardware} choices have been decided, clients can then lease the tools from 3devo.

In keeping with 3devo, this mannequin is threat free, with clients in a position to return tools if it’s not performing as hoped. Customers may return {hardware} as soon as it’s not required, saving cash in comparison with if they’d bought the {hardware} outright.

3devo may even work to tailor {hardware} to satisfy particular buyer necessities by means of co-development and co-creation. Furthermore, 3devo’s Superior assist extends past challenge completion, to make sure long-term challenge success and evolution.

“The leasing mannequin principally means that you would be able to get entry to the tools in a means the place you’re comparatively freed from failure, that means that when you don’t attain your purpose, you possibly can ship the tools again. You’re not financially dedicated,” defined Wesselink. “For those who’re carried out along with your innovation, then the {hardware} comes again, and we are able to place it at a buyer that does want it.”

Recycled 3D printing materials – a rising market

Rising the sustainability of 3D printing is a core concern throughout the business, with materials firms working to safe provide chains and decrease environmental influence by producing recycled merchandise. A Life Cycle Evaluation revealed by KIMYA final 12 months reported that utilizing recycled PETG filaments can cut back 3D printing CO2 emissions by as much as 35%.

California-based industrial designer Reiten Cheng developed an open-source system that may flip discarded plastic bottles into useful recycled 3D printing filament. Known as the ‘Polyformer,’ the elements of this modular machine may be 3D printed, permitting makers to simply fabricate their very own filament recycling system. Cheng has additionally revealed a free step-by-step information to constructing the Polyformer on GitHub.

Elsewhere, UK-based 3D printing filament producer Filamentive affords a variety of biodegradable and recycled filaments. Final 12 months, the corporate launched its Economic system PLA, made with as much as 99.99% recycled supplies. Marketed as a “probably eco-friendly possibility” within the 3D printing filament market, Economic system PLA is out there in black and white colours.

“We’re devoted to sustainability and constantly search methods to reduce our environmental footprint. The launch of Economic system PLA is a big step on this course,” commented Ravi Toor, Managing Director, Filamentive. “We imagine this product will resonate with clients looking for each sustainability and high-quality 3D printing filament.”

Extra not too long ago, Carbon fiber materials recycling specialist Vartega secured $10 million in fairness financing to develop and promote its 100% recycled carbon fiber strengthened filament.

Vartega’s proprietary recycling course of permits high-performance carbon fiber to be recovered and transformed into superior 3D printing supplies. The corporate hopes to additional combine its recycled materials with business companions within the additive manufacturing, automotive, client electronics, and sporting items sectors.

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of accessible roles and kickstart your profession.

Featured picture reveals a 3devo engineer engaged on a Filament Maker TWO. Photograph through 3devo.