3D Printing Industry Review of the Year: September 2022

Interested in reading more about the year’s biggest 3D printing news? Access our complete report. 3D Printing Industry Review of the Year You can find the series here.

September saw the return to McCormick Place, Chicago, of the International Manufacturing Technology Show. While usually held every other year, the COVID-19 pandemic meant this year’s edition was the first since 2018. The event doubled as a networking opportunity for attendees and a showcase for the latest production technology products.

Researchers also revealed technological advancements that could lead to future manufacturing opportunities. The UK’s largest 3D-printed infrastructure was built using 3D printing for construction.

You can read more about Carbon, Nikon, 3D Systems and Systemic Bio, as well as the City University of Hong Kong and Optisys.

IMTS recovers from COVID-induced hiatus

As always at IMTS, this year’s show allowed 3D printing firms to exhibit directly alongside the developers of other manufacturing technologies like injection molding or CNC machining. This gave attendees the rare opportunity to assess the future of 3D printing and identify its place in the wider manufacturing world.

As discussed in 3D Printing Industry’s IMTS breakdown, one of the headline announcements at the event was the launch of HP’s Metal Jet S100 3D printer. The firm’s long-awaited entry into the metal 3D printing space is designed to work with Metal Injection Molding (MIM) materials rather than spherical powders. It was stated that this would reduce the cost per part for system users.

Nexa3D debuted the QLS 820 3D printer. Inkbit displayed the Vista machine that it launched earlier in 2012. It features an algorithm that allows it to achieve a record 42% plate density.

3D Systems also displayed Certified CuNi30. This is a corrosion-resistant copper/nickel alloy originally designed for Huntington Ingalls Industries subsidiary Newport News. The product has been extended to a wider audience. In software, meanwhile, Oqton’s CEO Ben Schrauwen outlined how his company’s software first found dental applications, but it is now gaining traction in energy and oil & gas.

3D Systems and Nikon make strategic moves

Nikon purchased shares in Optisys, Hybrid Manufacturing Technologies and SLM Solutions after making a $622million bid earlier in the month. These deals allowed Nikon to increase its stakes in metal 3D printing as well as take another step towards its Vision 2030-led digital manufacturing goals.

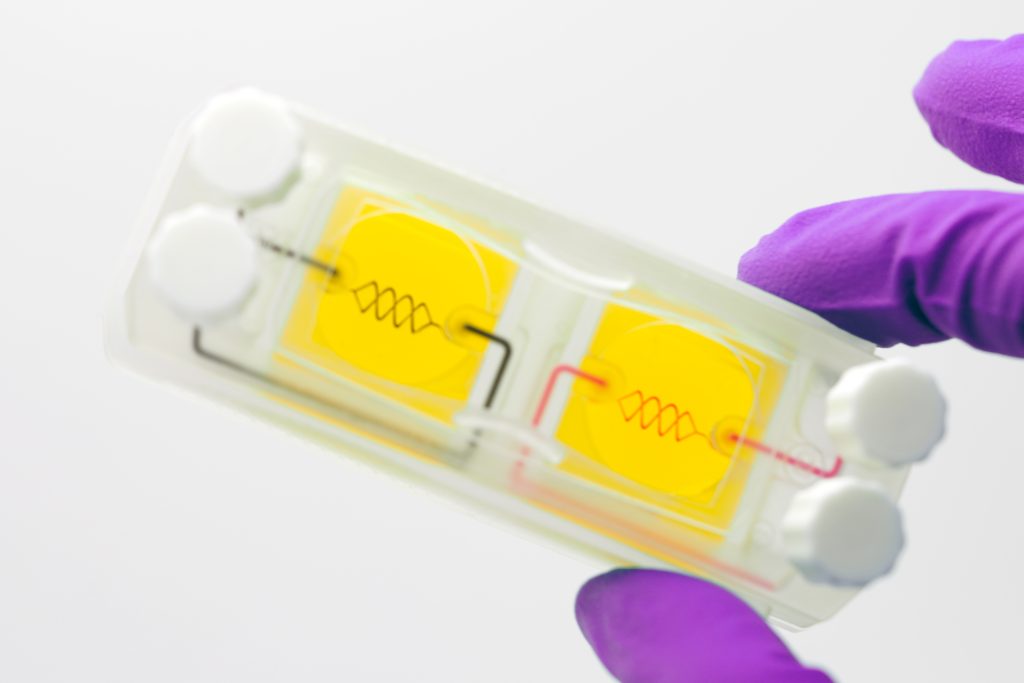

3D Systems spun off Systemic Bio, its 3D bioprinting division. Set to utilize the technologies developed as part of its parent firm’s Print to Perfusion program as well as those of its other subsidiary Allevi, the company is developing tissues for a human vascularized integrated organ system (h-VIOS) platform.

“In forming Systemic Bio, we are applying these core technologies to specifically address critical needs within the pharmaceutical market,” said Dr. Jeffrey Graves, CEO of 3D Systems. “With our potential to ultimately manufacture hundreds or even thousands of custom-designed, proprietary human tissue models, pharmaceutical companies can more rapidly and accurately evaluate the efficacy of developmental drugs in the lab, with the goal of reducing development time.”

Construction momentum continues to grow

In September, there were many positive developments in the construction industry. BAM and Weber Beamix built a 3D printed footbridge over a UK motorway in a process that was thought to lower the structure’s carbon footprint, reduce any risk of disruption and keep down costs by minimizing the use of molds.

ChangeMaker 3D collaborated with United Utilities in the UK to 3D print an 1.8-meter wastewater tank. The pair was able to reduce the lead time by using CyBe Construction technology to additively manufacture the bridge.

Researchers from the University of Virginia (UVA), however, have developed a novel way to 3D print living soils. These can be used for future carbon-negative building construction. With further R&D, the UVA team said their seed-impregnated soil ‘ink’ could replace less sustainable construction materials.

The UK and the US turn to AM for defense

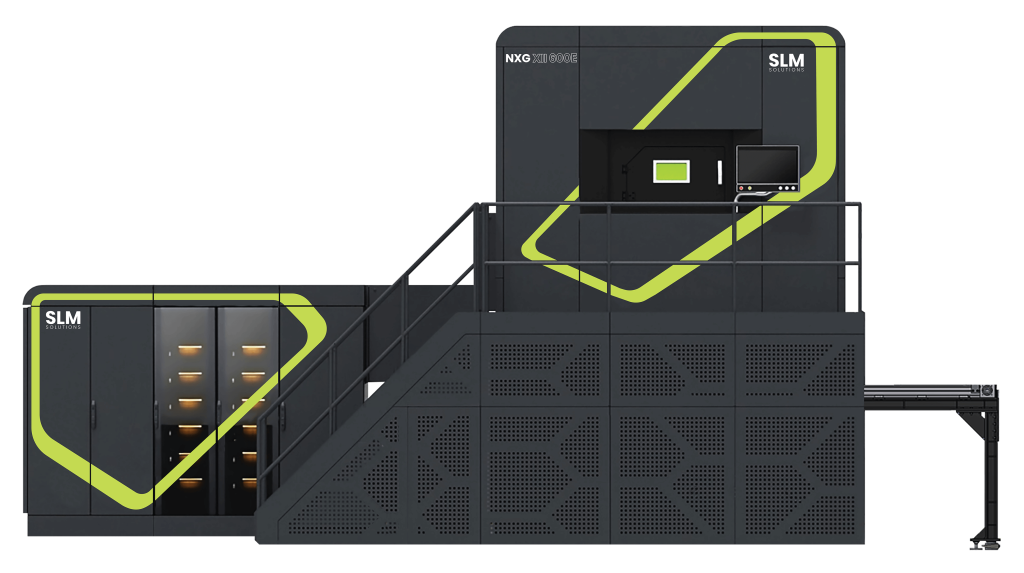

In September, another trend emerged: the strong desire of the UK Ministry of Defence (MoD), and the US Department of Defense(DoD) to adopt 3-D printing in military applications. That month, SLM Solutions announced that it had been subcontracted by the Concurrent Technologies Corporation to develop the ‘world’s largest metal 3D printer’ for deployment by the US Air Force.

According to the company, it was working on a 1.5-meter Z axis 3D printer version of its NXG XII 600 3D Printer. Set to be known as the ‘NXG XII 600E,’ the upcoming system is being designed to overcome the limits of current additive manufacturing equipment when it comes to creating long parts with critical defense applications.

It was announced in the UK that an MoD manufacturing supply network was in process of being established. The aim is to allow military-grade spares parts to be 3D printed as needed. As part of ‘Project TAMPA,’ the MoD aims to create a multi-supplier framework with the capacity to 3D print lighter, stronger metal parts as and when they’re needed.

Discovering the next step in 3D printing

University-developed technology is often the source of big breakthroughs in 3D printers. The results of many such projects were presented throughout the month. Scientists at the City University of Hong Kong came up with a way to partially carbonize parts in order to make 3D printed lattices stronger.

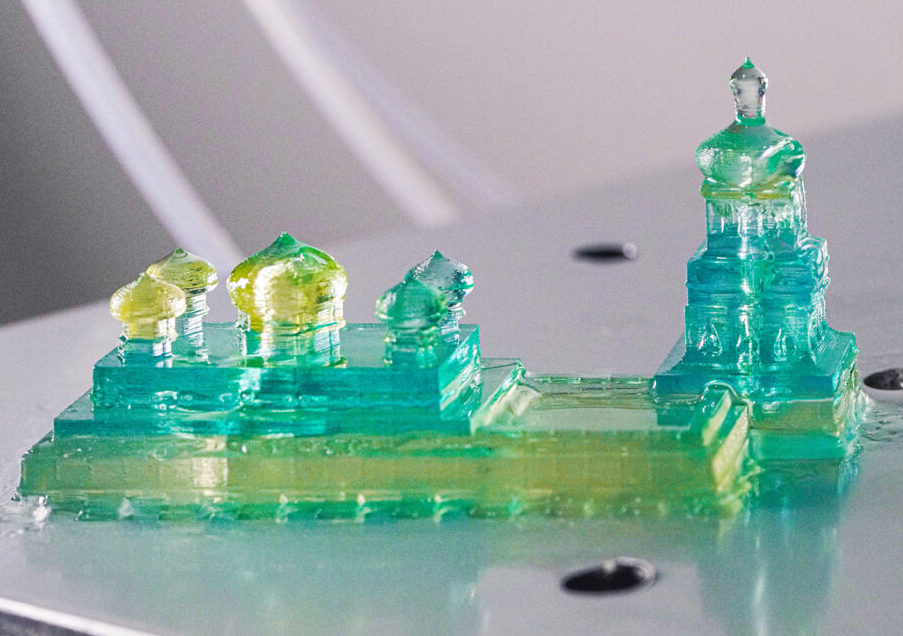

Researchers at Stanford University also announced the development of a ‘five to ten times faster’ resin 3D printing process. Essentially a fresh take on the Continuous Liquid Interface Production (CLIP) method developed by Carbon, the team’s ‘iCLIP’ approach sees the oxygen-filled ‘dead zone’ at the bottom of a CLIP printer’s resin pool repurposed.

The scientists were able to speed up the process by injecting more material into the space. This allowed them to create unique conduit-integrated parts. Carbon Co-Founder Joseph DeSimone, who turned out to be one of the co-authors of the team’s study, said the technology could “help to usher in a new era of digital manufacturing,” and “enable the fabrication of complex, multi-material objects in a single step.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter Follow us on Twitter, You can also like our page Facebook.

2022: 3D Printing Industry review and news

2021: 3D Printing Industry Review of Trends and News

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, and video shorts.

Are you interested in a job within the additive manufacturing sector? Visit 3D printing jobs For a list of available roles in the industry.

Featured photo shows McCormick Place’s staircase. McCormick Place is where IMTS-2022 will be held. Photo by Paul Hanaphy