10 Reasons Why DfAM Matters in 3D Printing

At this level, if you’re concerned with additive manufacturing, you recognize simply how essential design is for the creation of an element, with modeling being step one in any 3D printing course of. Enter Design for Additive Manufacturing, or DfAM as it’s extra generally recognized. Outlined as “design for manufacturability” for additive manufacturing, or extra merely because the design strategies and instruments that may optimize elements which are created utilizing additive manufacturing, DfAM permits customers to reap the benefits of the advantages of the design freedom that’s current in 3D printing and is essential to creating purposeful, high-performing elements. However, even with that information, DfAM is typically ignored within the trade. However why is it essential? What advantages can it deliver to elements? We discover these questions in our new editorial format the place we listing 10 the explanation why DfAM issues in 3D printing.

#1. Decreased 3D Printing Errors

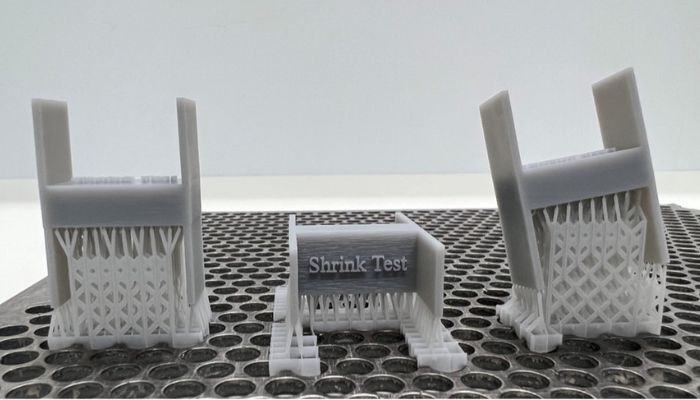

Printing failures are the bane of any person of additive manufacturing applied sciences. Particularly in terms of extremely industrial processes, corresponding to LPBF or SLS which use lasers, or costly supplies like PEEK and PEKK, small errors that smash the half can actually set customers again by way of value and time. That is the place the worth of DfAM turns into rapidly apparent. By design, it’s potential not simply to correctly orient and help the mannequin (each of which go a good distance in guaranteeing properties corresponding to isotropy and in guaranteeing there will likely be no warping), but additionally to permit customers to decide on the correct infill and layer settings for an element. This in flip considerably reduces print failures.

Correction orientation is without doubt one of the concerns in DfAM (photograph credit: Protolabs)

#2. Sooner Printing

Pace is a core advantage of additive manufacturing because the applied sciences allow customers to create elements at a fraction of the time that might be used with typical manufacturing strategies. Nevertheless, that pace just isn’t a given. Through the use of DfAM, it’s potential to optimize the design utilizing methods like lattice buildings to maintain the power whereas minimizing the quantity of fabric that must be used. It additionally will permit customers to attenuate help buildings which, as will likely be mentioned under, additionally cuts down on print time.

#3. Extra Complicated Designs

In 3D printing, there is no such thing as a extra problem concerned when a design is extra advanced. DfAM subsequently permits for customers to create considerably extra advanced geometries than those who could be made utilizing extra conventional design guidelines. By software program, elements that considerably extra advanced geometrically, particularly for metallic, will be designed after which printed. This complexity is the place we actually see the liberty that 3D printing brings to customers.

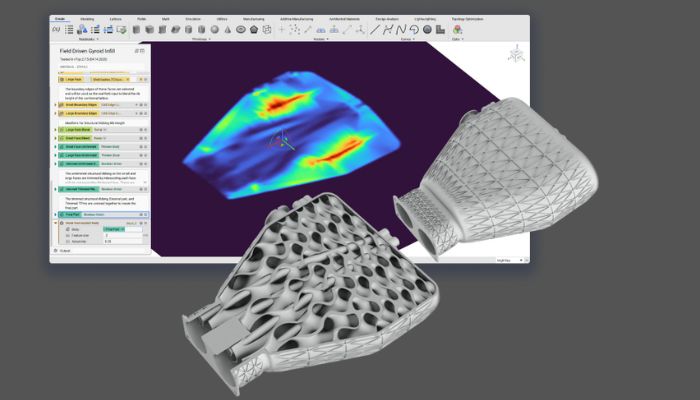

#4. Optimize Weight-Efficiency Ratio

Connecting to the earlier instance, DfAM additionally permits customers to reap the benefits of totally different design software program to completely optimize an element. We’ve heard about it time and time once more, one of many cause why 3D printing is so coveted in sectors like aerospace and automotive is as a result of it lets you create an element that’s considerably lighter whereas nonetheless preserving its power and different properties, that means a superior weight-performance ratio. This may be finished notably via DfAM, for instance by integrating lattice buildings or utilizing topological optimization and generative design for an element. These are particularly designed to optimize and generate elements to have much less materials whereas nonetheless assembly particular constraints like power. And whereas in conventional manufacturing, the ensuing elements will be too sophisticated to make, this isn’t an issue in 3D printing, as talked about above.

One of many ways in which DfAM can be utilized is with topological optimization (photograph credit: nTop)

#5. Fewer Assist Constructions

It may be straightforward to see help buildings as a “vital evil” in 3D printing. Whereas helps are completely vital for guaranteeing {that a} half is not going to deform or warp in the course of the 3D printing course of, additionally they imply extra materials use (affecting each value and time), which in flip could make post-processing longer in addition to have an effect on the look of the half. That is the place DfAM can play a job. By cautious design of elements, corresponding to decreasing overhangs, enhancing orientation or appropriately selecting infill settings, customers can have fewer helps when making elements.

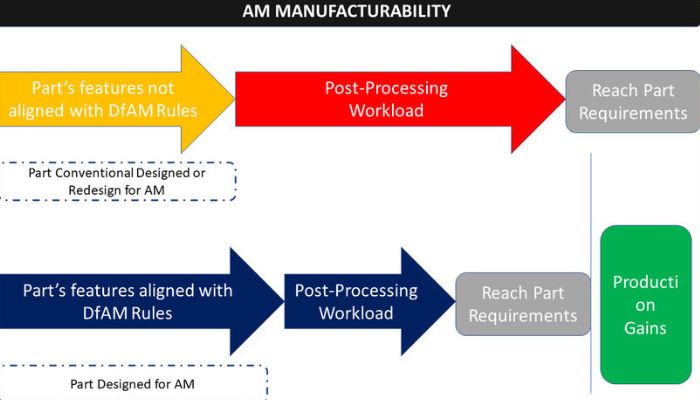

#6. Decreasing Submit-Processing

Persevering with from the earlier level, one other important cause that DfAM issues is that it’s going to permit customers to cut back total post-processing. After all, one of many principal causes that this may be finished is thru optimization of help buildings, that means much less time will likely be used on eradicating them, however there are additionally different concerns. For instance, by orienting the half appropriately or decreasing layer top (each essential concerns in DfAM), points corresponding to floor smoothness will be addressed already earlier than printing even begins. If these items should not thought-about, usually post-processing will take considerably longer, therefore the good thing about turning to DfAM.

#7. Half Consolidation

One more reason why DfAM issues is for half consolidation. An more and more common cause for utilizing additive manufacturing, particularly in sectors like aerospace and automotive, is the flexibility to consolidate a number of elements into one via extra advanced geometries. One instance of that is with the Czinger 21C hypercar the place the producer, Divergent 3D, claims that it have been capable of consolidate 1000’s of elements into just some hundred, considerably reducing the burden and growing efficiency. Any such consolidation is barely potential via 3D printing and will be finished by studying and adopting the rule of DfAM.

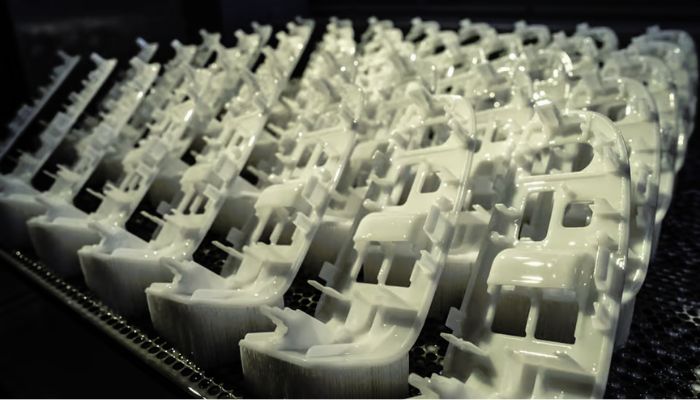

#8. Elevated Scalability and Mass Manufacturing

Admittedly, this subsequent level doesn’t essentially apply to every 3D printing know-how equally. Not all of them are well-suited to mass manufacturing or scalability for numerous causes. Nevertheless, for applied sciences like SLS, DMLS, resin 3D printing and binder jetting, DfAM can play a vital function in scaling up manufacturing. By DfAM, the utmost variety of elements will be positioned on the construct quantity via stacking. Taking DfAM under consideration will help customers overcome one of many main criticisms of 3D printing, that it isn’t well-suited to mass manufacturing.

Stacked 3D printed elements made utilizing resin 3D printing (photograph credit: 3D Methods)

#9. Price Optimization

Complicated geometries and lighter elements are key causes that DfAM issues, however what are the advantages of having the ability to create them if the associated fee is simply too nice? Fortunately, DfAM has truly been proven to additionally scale back value when making elements. In 2020, The Barnes Group argued that 86% of the price of the half in AM was pushed by design, and that has been confirmed time and again. Solely via design are you able to scale back the quantity of fabric used whereas persevering with to maintain power and different properties, in the end affecting the price of the half. Additionally, it’s essential to contemplate that extra advanced doesn’t imply dearer, the truth is relying on the design, it might be the alternative!

#10. Optimization primarily based on 3D know-how

Final, however actually not least, DfAM issues as a result of it permits customers to optimize the half primarily based on the particular 3D printing know-how used. There are seven households of 3D applied sciences with much more processes falling below them and it ought to go with out saying that there are important variations in them. One instance is powder-based applied sciences, the place designs ought to most likely combine escape holes to make sure that the elements are printed hole (which might not be a priority in FDM or resin 3D printing). In the meantime, in FDM 3D printing, anistropy is widespread, thus DfAM will help enhance isotropy on elements if vital.

What do you consider these 10 the explanation why DfAM issues? Do you already use DfAM when designing elements for 3D printing? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly publication right here, the newest 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.